Autonomous Mobile Manipulator Robots Market

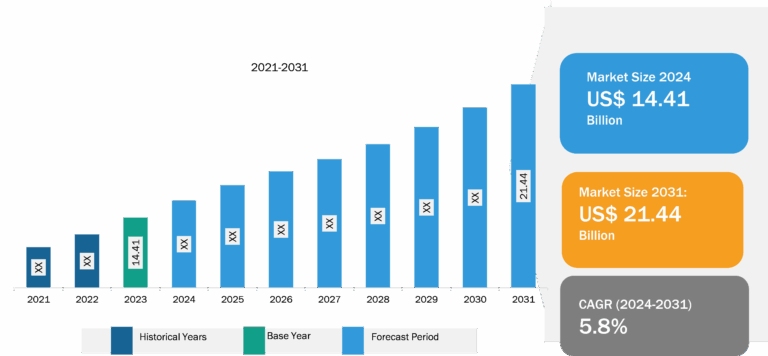

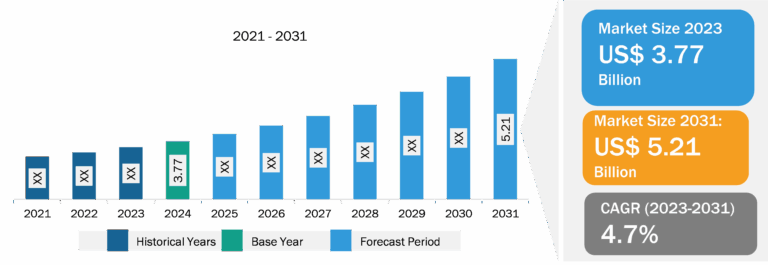

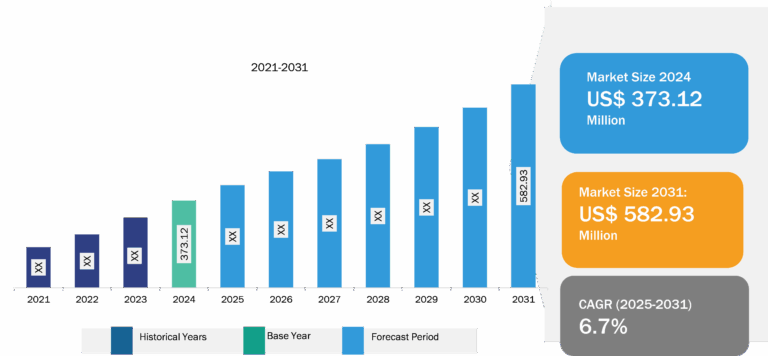

A few of the leading factors boosting the global autonomous mobile manipulator robots market growth are the rising e-commerce industry and increasing demand for automation solutions. Further, the increasing demand for AMMR in industry-specific applications and the expansion are expected to provide significant growth opportunities to the autonomous mobile manipulator robots (AMMR) market in the coming years.

The global autonomous mobile manipulator robots market is segmented on the basis of type, payload, application, and end user. Based on type, the global autonomous mobile manipulator robots market is bifurcated into differential and omnidirectional. Based on payload, the global autonomous mobile manipulator robots market is segmented as 3–5 kg, 5–10 kg, 10–20 kg, and 20 kg and above. Further, based on application, the global autonomous mobile manipulator robots market is categorized into sorting, pick & place, inventory management, and others. Based on end user, the global autonomous mobile manipulator robots market is segmented into healthcare, space, assembly, and others. Based on geography, the global autonomous mobile manipulator robots market is categorized into North America, Asia Pacific, Europe, the Middle East & Africa, and South America.

- In April 2023, Comau S.p.A., an Italy-based company, developed a mobile manipulator mounted on an autonomous mobile platform. This system was built for three different European Union (EU) projects.

- In October 2021, Plus One Robotics Inc. and Locus Robotics Corp. announced their plans for a strategic collaboration to develop an automated picking system; it merges mobile robots and stationary picking arms to help improve productivity in e-commerce fulfillment centers.

- In August 2019, KUKA AG launched a mobile manipulator robot as “the world’s first solution from a single source” for wafer handling during semiconductor manufacturing.

Industry 4.0 is transforming the way companies manufacture, process, and distribute their products. They are incorporating new technologies such as the Internet of Things (IoT), robotics, analytics, AI, and machine learning into their facilities to boost operational and production efficiency. Factory automation plays a crucial role in automating the manufacturing process to increase the production output in minimal time and reduce labor costs. In addition, it helps to improve the quality of the products by minimizing the risk of human errors. These factors are leading to a rise in the adoption of factory automation in several industries such as healthcare, automotive, and aerospace. Thus, to cater to the growing demand for automation, the market players are launching new solutions. DIMOFAC, the first project that was an initiative to help factories implement a smart factory architecture in Europe, where the system can be used for the pick-and-place operation and other warehouse automation tasks. PeneloPe project was the second project in the region, where the mobile manipulator can be used for glue dispensing and quality inspection in the public transport domain. The third application of the system is for the ODIN project; it supports the management of mechanical parts in automotive applications. Therefore, the growing demand for automation in various industries is propelling the global autonomous mobile manipulator robots market growth.

The global autonomous mobile manipulator robots market is segmented into North America, Europe, Asia Pacific (APAC), Middle East & Africa (MEA), and South America. Asia Pacific held the largest market share in 2022, followed by Europe and North America. In Asia Pacific, government initiatives and policies supporting the automation of manufacturing plants are the significant factors boosting the adoption of AMMR. For instance, under “Made in China 2025,” the government of China has released a five-year smart manufacturing development plan to build robots and upgrade their manufacturing plants. Also, the presence of several autonomous mobile manipulator robots market players such as Doosan Robotics, Adin Robotics, Korea Institute of Industrial Technology (KITECH), and OMRON leads to new product launches, partnerships, and other strategic initiatives to grow their revenue; these factors fuel the autonomous mobile manipulator robots market growth in Asia Pacific.