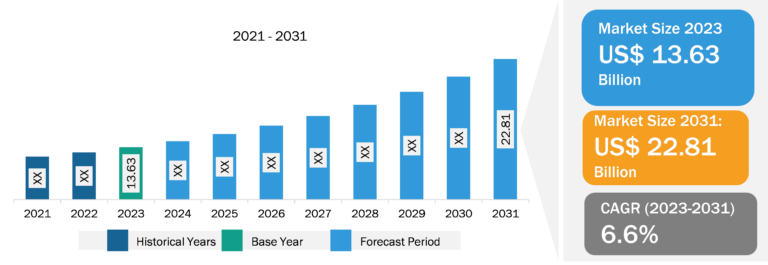

Industrial Absorbents Market

Oil spills are long-lasting environmental disasters with a wide range of impacts. The effects of oil spills can vary, ranging from minimal to serious ones, depending on the magnitude and location of the spillage. Oil can kill surface-dwelling animals and birds by poisoning or suffocating them, or by affecting their buoyancy and natural waterproofing abilities. Contaminated food supplies may lead to the malnourishment of animals, which may be followed by poisoning over time. The damage can be significant if oil spills happen in an area with wildlife. Oil obstructs the insulating ability of fur on mammals and impacts the water-repelling qualities of a bird’s feathers. Without insulation or water-repelling qualities, mammals and birds can die from hypothermia. Further, oil and oil products (petroleum products) have many volatile compounds that are emitted as gases. These gases may or may not produce strong chemical odors but can contaminate the surrounding air, which could lead to health risks when exposed to these compounds for a prolonged period. Moreover, once in the air, pollutants can travel over long distances. The original contamination levels at the source and specific weather conditions may dictate the final spread of oil-contaminated air vapors. Oil spills, leading to oil slicks and sheens, also harm the aesthetic appeal and recreational value of coastal waters, shorelines, beaches, wetlands, etc. Serious consequences include the discontinuation of recreational activities in these areas, at least temporarily, until the spill is removed and the cleanup process is completed.

The incidences of oil spills may further have immediate effects on humans, fish, animals, birds, and wildlife, in general, if they come in direct contact with the spilled oil, breathe in volatilized oil components, consume food contaminated at any level in the food chain, and so on. Governments of various countries have implemented regulations concerning oil and chemical spills. For instance, Section 14 regulations of the Canada Oil and Gas Operations Act prescribe measures necessary to prevent air, land, or water pollution due to the exploration and drilling, production, storage, transportation, distribution, and other operations in the oil & gas industry. Therefore, growing concerns about the environment and the associated regulations to prevent oil spills bolster the demand for industrial absorbents across the world.

Industrial Absorbents Market: Segmental Overview

Based on product type, the industrial absorbents market is segmented into pads, rolls, pillows, booms, socks, and others. In 2023, the booms segment held the largest market share. An absorbent boom is a temporary floating barrier used to contain an oil spill. Booms reduce the possibility of polluting shorelines and other resources and help make the recovery from spills easier. Absorbent booms also help improve the efficiency of vacuums, skimmers, or other collection methods by aiding in the concentration of oil in thicker surface layers. Absorbent booms are often made of closed-cell, polyethylene foam shaped into circular sections. The boom is kept vertical with the use of ballast, which adds weight at the bottom of the skirt to provide stability. Oil containment booms are designed to meet different operating environments. They come in various shapes and sizes, with different levels of effectiveness in different types of water conditions. Further, the socks segment is expected to register the highest CAGR from 2023 to 2031. Absorbent socks consist of a long, enclosed tube filled with granular materials that block, absorb, and sometimes chemically treat liquid spills. Their flexibility provides a snug fit to prevent seepage and retain fluids for a longer period.

Based on type, the industrial absorbents market is segmented into universal, oil-only, and hazmat/chemical. In 2023, the hazmat/chemical segment held the largest market share. The universal segment is expected to record the CAGR during the forecast period. Chemical absorbents have the potential to efficiently clean all types of hazardous chemicals from spills or leaks. They can absorb aggressive chemicals and clean up the residues. Chemical absorbents are available in different shapes, sizes, and dimensions. These are usually made up of polypropylene and polyester. These pads can absorb a wide range of chemicals, such as acids, bases, petroleum-based fluids, coolants, non-aggressive chemicals, and aqueous-based solutions.

Based on end-use industry, the industrial absorbents market is segmented into oil & gas, chemical, food processing, healthcare, automotive, and others. In 2023, the oil & gas segment held the largest industrial absorbents market share. As oil and chemical spills are common in the oil & gas industry, the use of industrial absorbents is considerably high, as these can help avoid the hazardous effects of oil spills. Industrial absorbents have hydrophobic fibers that repel water (and float) and absorb only oils and other hydrocarbons. These absorbents float on water even when they are saturated, owing to which these pads are ideal for use in wet conditions. The chemicals industry in developing countries such as China, India, and Saudi Arabia is flourishing significantly with the increasing global demand for various chemicals and intermediates. Industrial absorbents such as diatomaceous and sepiolite earth are an important part of the chemicals industry as they help absorb chemicals spilled during manufacturing or transportation and minimize the impact of spills on the environment. Thus, the chemicals segment is expected to record the highest CAGR in the industrial absorbents market during the forecast period.

Industrial Absorbents Market: Competitive Landscape

3M Co, Ansell Ltd, Brady Corp, Decorus Europe Ltd, Meltblown Technologies Inc, Oil-Dri Corp of America, Schoeller Industries, Fentex Ltd, Complete Environmental Products Inc, TOLSA SA, SpillTech Environmental Inc, New Pig Corp, Empteezy Ltd, and Green Stuff Absorbentes are among the key players operating in the global industrial absorbents market. Players operating in the market focus on providing high-quality products to fulfill customer demand.