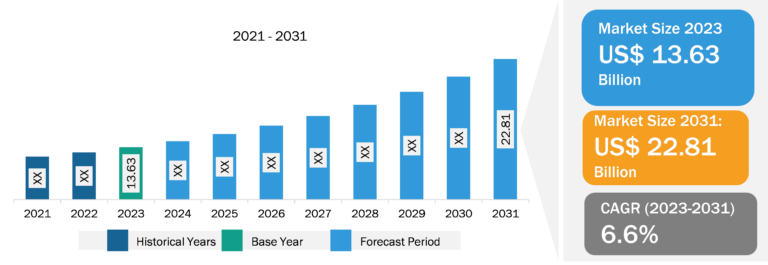

Abrasive Market

Abrasives are made of extremely hard materials that can be used to process other materials by wearing the surface of the material to be processed. Abrasives are highly used for various industrial processing. Abrasives are of natural or synthetic origin and are distinguished by their degree of hardness. They are particularly important in the metallurgical and automotive industries. The manufacturing process of abrasives varies according to the product type, such as bonded abrasives and coated abrasives. Abrasive grain processing is the primary stage of abrasive manufacturing. It involves graded crushing and close sizing of natural or synthetic abrasives. The crushed grains are separated into specific grade sizes through a screening process. Automotive, aerospace, marine, woodworking, electrical & electronics, and metal fabrication are among the major end-use industries in the abrasive market.

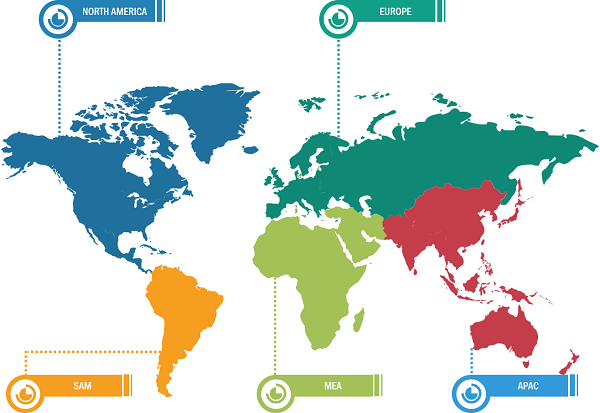

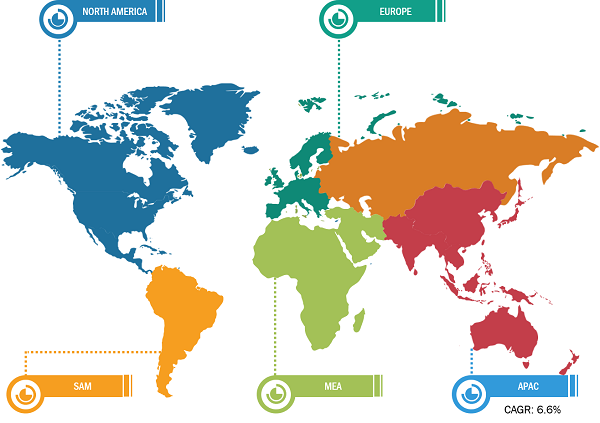

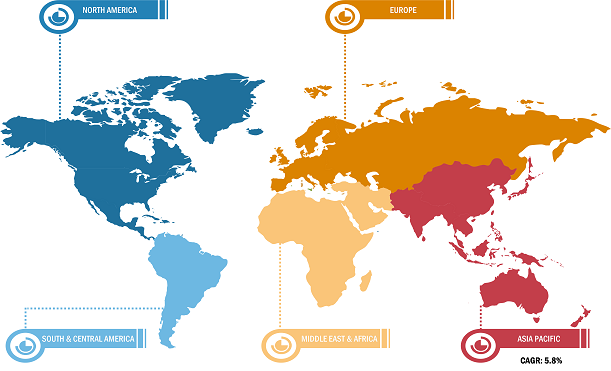

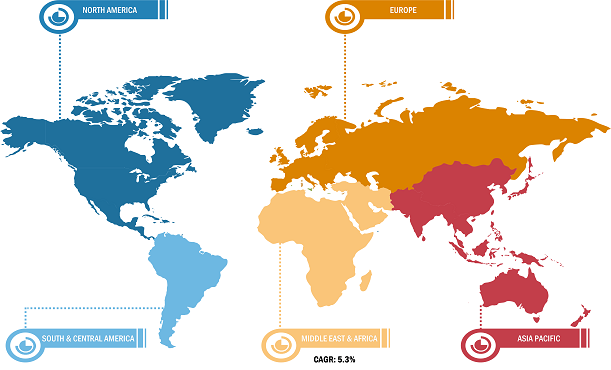

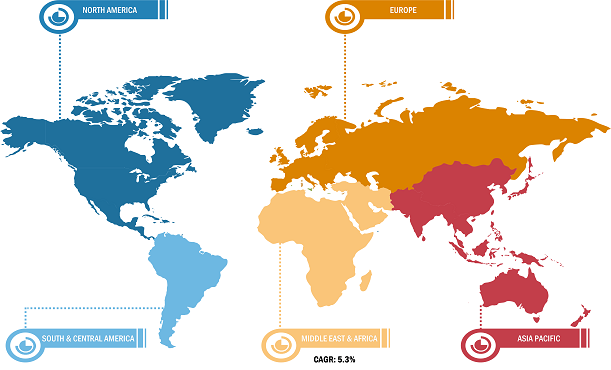

In 2022, Asia Pacific dominated the abrasive market. The market in Asia Pacific is driven by accelerating automotive, marine, aerospace, and construction industries. Asia Pacific is a hub for automotive manufacturing with a large presence of international and domestic players operating in the region. According to a report published by the China Passenger Car Association, in 2022, Tesla Inc delivered 83,135 made-in-China electric vehicles, indicating growth in sales of electric vehicles compared to 2021. According to the Organization Internationale des Constructeurs d’Automobiles (OICA), Asia-Oceania’s vehicle production increased from 46.8 million in 2021 to 50 million in 2022. The automotive sector’s growth, coupled with the demand for lightweight materials and electrical vehicles, further propels the utilization of specialized abrasives tailored to these evolving requirements. The rising development of sustainable abrasives in the region is expected to remain an abrasive market trend.

Adoption of Abrasives in Automation and Robotic Applications Drive Abrasive Market Growth

The abrasive market report emphasizes the key factors driving the market. According to the report published by the International Federation of Robotics in 2022, the total annual robot installations worldwide reached 517,385 units in 2021, a rise of 31% compared to 2020. The automotive industry registered ~119,000 units of annual robot installations worldwide, accounting for 23% of total robot installations in 2021, significantly driven by the component supplier segment. According to a press release by the International Federation of Robotics in 2023, robot density in South Korea was estimated at 2,867 industrial robots per 10,000 employees.

In contrast, in China, robot installations in the automotive industry reached 61,598 units in 2021, accounting for 52% of the global robot installation share. In 2021, nearly 380,911 units of robots were installed in Asia, a rise of 38% compared to the 2020 level. Industrial robots are gaining the highest demand from end-use industries such as automotive and electronics original equipment manufacturers. The increase in the use of robots in end-use industries is attributed to the reduction in the average selling price of robots. According to Castrol Ltd’s research, more than 4 million industrial robots are expected to be operational worldwide by 2025.

Abrasives are significant components for facilitating tasks such as grinding, polishing, and deburring with unparalleled accuracy and consistency. The adoption of abrasive-equipped robots streamlines production processes, minimizes downtime, and leads to cost savings. Market players, such as 3M Co, VSM Abrasives, and Norton Abrasives, offer abrasives with distinct characteristics for robotic applications. As automation continues to evolve, the utilization of abrasives with robotics is expected to revolutionize industrial manufacturing, offering high precision, productivity, and performance. Thus, the adoption of abrasives in automation and robotic applications is expected to influence the abrasive market growth during the forecast period positively.

Abrasive Market: Segmental Overview

The abrasive market analysis has been carried out by considering the following segments: material, type, application, and sales channel. Based on material, the market is segmented into natural and synthetic. In 2022, the synthetic segment held the largest abrasive market share and is expected to register the highest CAGR from 2022 to 2030. Synthetic abrasives are also called manufactured or artificial abrasives. A few of the common synthetic abrasives include boron carbide, silicon carbide, titanium carbide, and aluminum oxide. Synthetic abrasives are manufactured under controlled conditions in a closed electric furnace to avoid the introduction of impurities and to achieve the necessary temperature required for the chemical reaction.

Based on type, the market is bifurcated into bonded abrasives and coated abrasives. The bonded abrasives segment held the largest abrasive market share in 2022. Bonded abrasives are manufactured by combining grains with bonding agents, shaping the mixture, and then firing or baking the resultant product. Bonded abrasives are attached to a binder; the commonly used binders in abrasives are of rubber, glass, resin, or clay. Bonded abrasives are used with a drill or rotary tool. Grinding discs are widely used in metal fabrication applications and are available in various sizes and thicknesses. The grains are bonded together with a resin or binding agent to offer support to the grinding surface while cutting.

Abrasive Market: Competitive Landscape and Key Developments

3M Co, Saint-Gobain, Sia Abrasives Industries AG, Deerfos, Tyrolit, INDASA, Mirka Ltd, Cumi Awuko Abrasives Gmbh, Bosch Limited, Hermes Schleifmittel Gmbh, VSM AG, and SAIT Abrasivi SpA are a few players profiled in the abrasive market report. Players operating in the market focus on providing high-quality products to fulfill customer demand.

Key Developments

- In November 2023, VSM AG launched the successor to its STEARATE Plus series: VSM ALU-X. ALU-X is a new line of abrasives created by VSM to fulfill the special requirements of grinding nonferrous metals and to replace the well-known VSM STEARATE and STEARATE Plus series.

- In September 2023, Tyrolit Schleifmittelwerke Swarovski AG & Co KG acquired a complete stake in Acme Holding Company, a specialized abrasive producer and supplier, to enhance its portfolio for the foundry, steel, and rail sectors.

- In August 2023, VSM AG expanded its manufacturing plant by 50,000 sq ft. This extension sought to boost manufacturing capacity and shipping capabilities by assigning extra space for shipment, finished items, and jumbo materials.