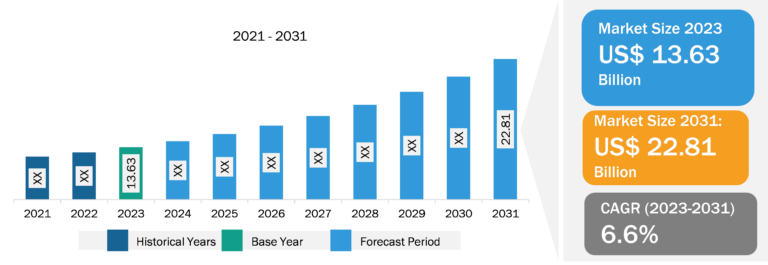

Microcarriers Market

Automation of Cell and Gene Therapy Manufacturing Services Emerging as New Trend in Microcarriers Market

Incorporating automation in cell and gene therapy manufacturing would lead to a reduced risk of contamination, improved consistency, and decreased cost of production. Lonza Cocoon and the CliniMACS Prodigy system from Miltenyi are a few of the devices available in the market that have been designed to enable the automation of extremely sequential unit operations for a CAR-T process within a single system. The rising demand for cell and gene therapies has shifted production from a small-volume process to a large-volume process worldwide. The progress of cell and gene therapy from an academic and clinical setting to mass production and commercialization further propels the demand for automation in commercial manufacturing.

In July 2020, Thermo Fisher Scientific Inc. and Lyell Immunopharma partnered to develop processes to design effective cell therapies for cancer patients. Under this partnership, the companies aim to improve the capability of T-cells and support the development of an integrated platform (system and software) complying with current good manufacturing practices (cGMP), along with reagents, consumables, and instruments. Further, government-aided organizations are adopting automation in the manufacturing of cell therapies to increase the national production capabilities of the country. As of March 2023, the UK Stem Cell Bank of the Medicines and Healthcare Products Regulatory Agency (MHRA) was testing automated robotic technology for developing stem cell technology for the manufacturing of stem cell-based therapies. Thus, automation is emerging as a new trend in the microcarriers market.

Microcarriers Market: Segmental Overview

Based on product, the microcarriers market is segmented into microcarrier beads, and media and reagents. In 2022, the microcarrier beads segment held a larger market share, and it is further expected to register a faster CAGR during 2022–2030. The microcarriers market, by equipment, is segmented into bioreactors, culture vessels, and others. In 2022, the bioreactors segment held the largest market share, and the same is estimated to register the fastest CAGR during 2022–2030. Bioreactors are manufacturing devices or vessels in which biological reactions are carried out; they are used to grow microorganisms such as yeast, bacteria, or animal cells in an appropriate environment under controlled conditions. Bioreactors are used in the production of vaccines, antibodies, or biological products. They are also used to produce pharmaceutical products used in the treatment of chronic diseases. In a microcarrier-based bioreactor, small microcarrier beads serve as the substrate for the human mesenchymal stem cells (hMSCs). The cells adhere to these beads and grow at a very high surface-to-volume ratio, which results in the highest possible volumetric cell productivity. A microcarrier-based bioreactor allows real-time off-line monitoring of cell growth and quality and metabolite analyses, which can be used to detect errors and rectify them immediately.

In terms of application, the microcarriers market is segmented into biopharmaceutical production, cell and gene therapy, tissue engineering and regenerative medicine, and others. In 2022, the biopharmaceutical production segment held the largest market share, and is estimated to register the fastest CAGR during 2022–2030. Based on end user, the microcarriers market is divided into pharmaceutical and biotechnology companies, contract research organizations and contract manufacturing organizations, and academic and research institutes. The pharmaceutical and biotechnology companies segment holds largest market share in 2022. The same segment is estimated to register the highest CAGR from 2022 to 2030.

Microcarriers Market: Competitive Landscape and Key Developments

Teijin Ltd, Bio-Rad Laboratories Inc, denovoMATRIX GmbH, Sartorius AG, Danaher Corp, Corning Inc, Eppendorf SE, Percell Biolytica AB, Asahi Kasei Corp, and Polysciences Inc are among the leading companies operating in the microcarriers market. The focus of these players is on expanding and diversifying their market presence and acquiring a novel customer base, tapping prevailing business opportunities in the microcarriers market.

- In June 2023, Teijin Ltd introduced new nonwoven microcarriers for the rapidly growing large-scale cell culture. This scaffolding substance promotes three-dimensional adhesion, facilitating the growth of a variety of cell types.

- In May 2022, the denovoMATRIX released beadMATRIX for mesenchymal stromal cells (MSCs). beadMATRIX are ready-to-use, pre-coated microcarriers free of animal components that are used to cultivate superior MSCs in vitro. Shaker bags, stirred tanks, vertical wheel bioreactors, and shaker flasks are the perfect environments for beadMATRIX.

- In June 2023, NOVA, a Saint-Gobain Life Sciences’ investment arm, announced an investment into denovoMATRIX. As an extension of the master service agreement that focuses on products related to the stem cell therapy market, both parties aimed to consolidate their relationship, thereby leveraging the global reach of Saint-Gobain Life Sciences and the innovative product line of the denovoMATRIX team.