Lubricating Grease Market

Lubricating grease is a specialized lubricant that plays a crucial role in minimizing friction and wear in mechanical systems. It is a semi-solid substance formulated by blending base oil with thickeners and additives. The base oil provides the primary lubricating properties, while thickeners enhance the viscosity, giving the grease its semi-solid consistency. This unique composition allows the grease to adhere to surfaces, forming a protective layer that withstands various operating conditions. Lubricating grease is vital in numerous industries, playing a crucial role in reducing friction, preventing wear, and ensuring the smooth functioning of various mechanical components. One of the major end-use industries is the automotive sector, where grease is extensively employed in wheel bearings, chassis components, and other moving parts to enhance performance and extend the lifespan of vehicles. In industrial manufacturing, lubricating grease is widely applied in machinery such as bearings, gears, and sliding surfaces. Its use contributes to efficient equipment operation, minimizing downtime and maintenance costs. The aerospace industry relies on grease for critical components such as landing gear, actuators, and other moving parts to maintain the reliability and safety of aircraft. Marine applications benefit from the protective qualities of lubricating grease, as it is utilized in equipment such as propeller shafts and winches, offering resistance against corrosion and ensuring optimal maritime conditions. In the mining industry, grease is indispensable for heavy machinery, conveyor systems, and bearings, providing essential lubrication to withstand the harsh and abrasive environments common in mining operations. The growing demand from these industries is driving the lubricating grease market growth.

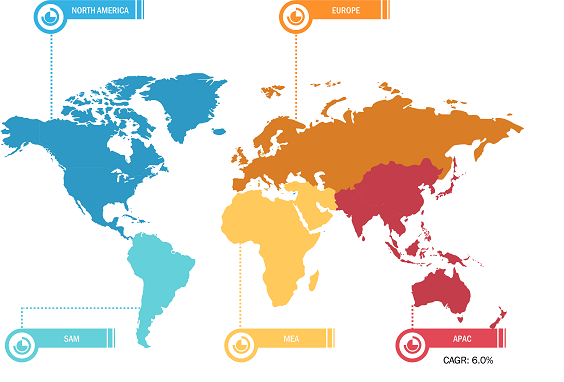

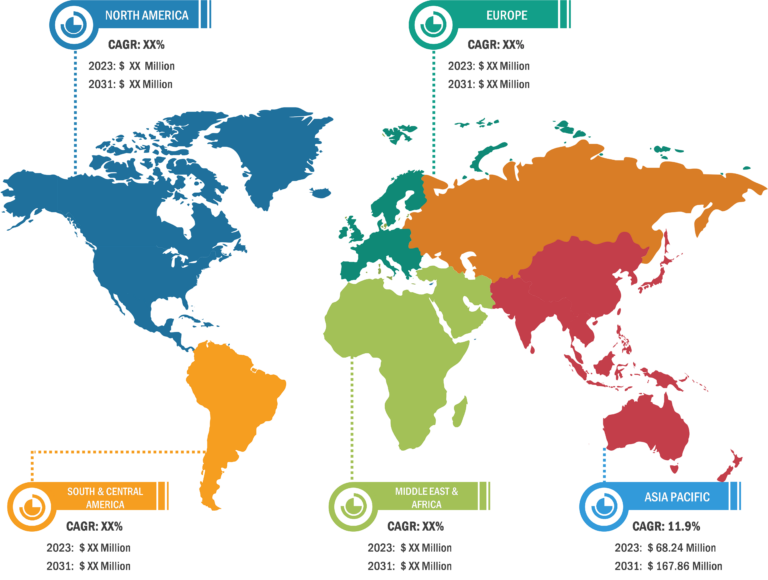

In 2022, Asia Pacific dominated the lubricating grease market. China, Japan, and South Korea are leading countries in the shipbuilding sector. According to the States Council of the People’s Republic of China, the shipbuilding output of China was 9.61 million deadweight tons (dwt) in 2022, i.e., up by 2.8 percentage points year-on-year, accounting for 46.2% of the global total. Shipbuilding greases confer properties such as resistance to elements and corrosive saltwater, resistance to high pressure, and increased lifespans for ship components. Furthermore, according to the report published by the US Geological Survey in 2022, China was the largest supplier of twenty-five non-fuel mineral commodities to several other countries in 2021. Out of twenty-five listed minerals, China produced sixteen critical minerals. The growth of end-use industries such as wind power, aerospace, automotive, and shipbuilding are expected to bring new lubricating grease market trends in the coming years.

Strategic Initiatives by Key Market Players Propel Lubricating Grease Market

The key manufacturers operating in the market are investing significantly in strategic development initiatives such as product innovation, R&D, mergers & acquisitions, and business expansion to attract a wide customer base and enhance their market position. In 2023, ExxonMobil announced the investment of nearly US$ $110 million (INR 900 crore) to build a lubricant manufacturing plant at the Maharashtra Industrial Development Corporation’s Isambe Industrial Area in Raigad. In 2021, TotalEnergies renewed its Global Partnership with Peugeot, Citroën, and DS Automobiles and extended it to Opel and Vauxhall. In 2023, TotalEnergies Lubrifiants accelerated the incorporation of recycled plastics into its Lubricant Bottles with TotalEnergies Polymers. In 2022, Pennzoil-Quaker State Company d/b/a SOPUS Products, a wholly owned subsidiary of Shell USA, Inc. that comprises Shell’s US lubricants business, acquired TFH Reliability Group, LLC, the parent company of Allied Reliability Inc. Thus, rising strategic product innovations and research by key market players are expected to create lucrative opportunities for the lubricating grease market during the forecast period.

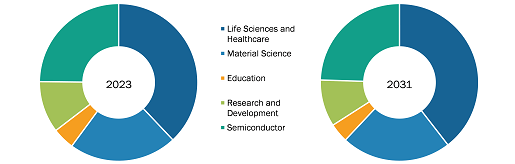

Lubricating Grease Market: Segmental Overview

On the basis of base oil, the lubricating grease market is divided into mineral oil, synthetic oil (polyethylene glycol, polyalphaolefin, and esters), and bio-based. In 2022, the mineral oil segment held the largest market share, and the bio-based segment is expected to register the highest CAGR from 2022 to 2030. Mineral oil is an inert, clear, odorless liquid and a chemically stable ingredient that is most widely used in common topical applications. It is made from highly purified, refined, and processed petroleum. The crude mineral oil is not purified or refined, making it preferable for railroad, automotive, and aviation industries. Mineral oil is used as a fluid component for the production of greases. These mineral oil-based greases offer excellent performance in most industrial applications. The mineral oil-based grease has excellent thermal stability and can be operated at various temperature ranges. This stability makes the grease suitable for use within the industrial and automotive industries. Mineral oil is also used in the food processing industry. It is preferred in various food processing equipment, particularly in the production of lubricating grease used by food and drink producers. These factors led to the dominance of the mineral oil segment.

Based on thickener type, the market is segmented into lithium, lithium complex, polyurea, calcium sulfonate, anhydrous calcium, aluminum complex, and others. The lithium segment held the largest lubricating grease market share in 2022. Calcium sulfonate greases are manufactured by converting a fluid detergent containing amorphous calcium carbonate to a grease containing calcite particles. The thickener property of calcium sulfonate provides excellent water-resistance and does not break down even in the presence of water. Calcium sulfonate-based greases are also used in motor-operated steam valves of nuclear plants and thermal-generating stations to control high-pressure steam. The calcite particles in calcium sulfonate greases make them a good choice for high-temperature applications. Calcium sulfonate greases offer various benefits, such as good rust performance and excellent oxidation stability.

Lubricating Grease Market: Competitive Landscape and Key Developments

Exxon Mobil Corp, Fuchs SE, Petroliam Nasional Bhd, Shell Plc, Kluber Lubrication GmbH & Co KG, TotalEnergies SE, BP Plc, Chevron Corp, Valvoline Inc, and Axel Christiernsson AB are a few players operating in the global lubricating grease market. Players operating in the market focus on providing high-quality products to fulfill customer demand.

Key Developments

- In November 2022, Chevron unveiled additional environmentally acceptable lubricants for marine vessels.

- In June 2021, Automotive components manufacturer Steelbird International ventured into the automotive lubricant space. Focused on four-stroke two-wheelers, they’ve launched a new range of engine oils, grease, and fork oils.