Slip and Tier Sheet Market

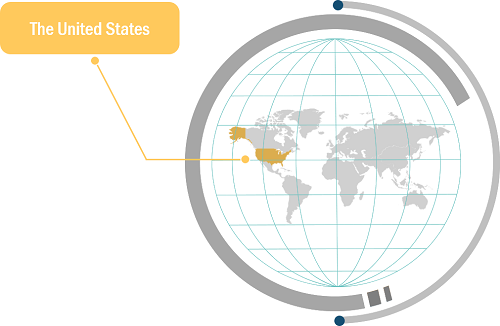

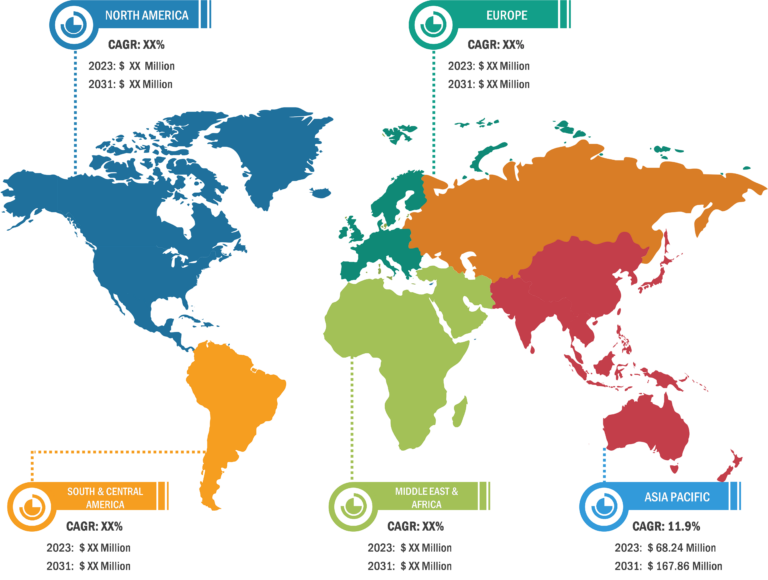

In 2023, North America held the largest global slip and tier sheet market share. In North America, the market for slip and tier sheets is mainly driven by their increasing use in different end-use industries. The US—one of the key economies in North America—contributes significantly to the growth of the slip and tier sheet market. The US slip and tier sheets market is driven by factors such as the increase in demand for slip and tier sheets from various end-use industries, strong growth of the e-commerce & logistics sector, and the rise in the number of warehouses in California. The number of warehouses is increasing in California owing to the growth in e-commerce selling. A large number of consumers are purchasing items online, requiring businesses to develop more warehouse space to meet the increased demand. Small and large businesses are looking for options to help fulfill their customer’s online orders, with online shopping becoming a popular and convenient consumer purchasing option.

High Demand for Plastic Slip Sheets

Plastic slip sheets are made from high density polyethylene and polypropylene. These plastic slip sheets can be manufactured from 100% recyclable, high density polyethylene. Plastic slip sheets are highly suitable for humid or freezing conditions as they are resistant to water and moisture. These sheets are also suitable for overseas exports. A few players operating in the slip and tier sheet market are offering plastic slip sheets with an anti-slip coating. The surface of such plastic slip sheets is rough, which increases the friction between the load and the slip sheet; hence, these sheets have better stability. Thus, the high demand for plastic slip sheets is predicted to offer more lucrative opportunities for the growth of the global slip and tier sheet market in the coming years.

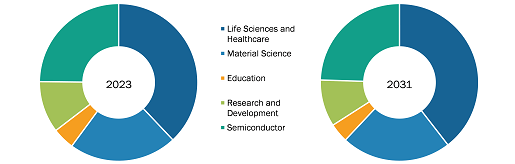

Slip and Tier Sheet Market: Segmental Overview

Based on material, the slip and tier sheet market is segmented into kraft paperboard, corrugated fiberboard, high density polyethylene, and others. The kraft paperboard segment held the largest share of the market in 2023. Kraft paperboard is cost-effective and lightweight; hence, it is used for protecting and packaging products during transportation. High density polyethylene is another major material segment in the slip and tier sheet market. High density polyethylene is durable and lightweight. Its advantages include high non-tear strength, longer sheet life, and storage in cold or humid environments. Products packed with high density polyethylene slip and tier sheets are handled by a lift truck, roller conveyor, automated guided vehicle (AGV), or powered unit load transportation devices.

Based on end-use industry, the slip and tier sheet market is segmented into food and beverage, consumer electronics, chemicals, pharmaceuticals, retail, and others. The food and beverage segment held the largest share of the slip and tier sheet market in 2023. Slip and tier sheets are mainly used in the food & beverages industry as a replacement for traditional wooden pallets to avoid damage. Consumer electronics is another major end-use industry in the slip and tier sheet market. A few examples of consumer electronics are digital cameras, small home and kitchen appliances, and mobile phones, among others. A slip sheet is used in the packaging and shipping of such electronic products. A slip sheet is used for product protection and stability. Increasing government investment in electronic product manufacturing and rising demand for consumer electronics are driving the consumer electronics industry growth. Retail is also one of the major end-use industries in the slip and tier sheet market. In the retail industry, slip and tier sheets are commonly used to transport retail products such as furniture, clothing, and personal care and cosmetics products. Slip and tier sheets are widely used for packaging different retail products as they are disposable, recyclable, lightweight, and cost-effective. With the growth of the online retail sector, online retailers have become one of the largest consumers of slip and tier sheets. The online retail sector is flourishing, with the rising demand for last-mile connectivity, increasing disposable income of people, and changing consumer preferences. Thus, with the growth of the overall retail sector, the demand for slip and tier sheets is also increasing.

Slip and Tier Sheet Market: Competitive Landscape and Key Developments

Fresh Pak Corp, International Paper Co, Georgia-Pacific LLC, Signode Industrial Group LLC, WestRock Co, Dura-Fibre LLC, Smurfit Kappa Group Plc, Crown Paper Converting, Eltete TPM Oy, and Sonoco Products Co are among the prominent players profiled in the slip and tier sheet market report. Players operating in the global market focus on providing high-quality products to fulfill customer demand. Also, they focus on adopting various strategies such as new product launches, capacity expansions, partnerships, and collaborations in order to stay competitive in the market.

Key Developments

- In September 2023, Sonoco Products Co announced that it had completed the acquisition of the remaining equity interest in RTS Packaging, LLC from joint venture partner WestRock and one WestRock paper mill in Chattanooga, Tennessee. This acquisition will strengthen and expand Sonoco’s 100% recycled fiber-based packaging solutions to serve growing consumer wine, spirits, food, beauty, and healthcare markets. With this acquisition, Sonoco added a network of 15 operations and 1,100 employees in the US, Mexico, and South America.

- In November 2021, Badger Paperboard—a chipboard converting company headquartered in Fredonia, Wisconsin—announced the acquisition of Falcon Packaging in Houston, Texas. The addition of Falcon Packaging’s full converting and warehousing facilities in Houston will expand Badger’s footprint and production capabilities.