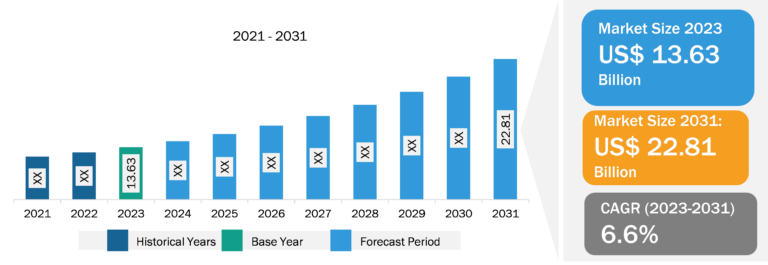

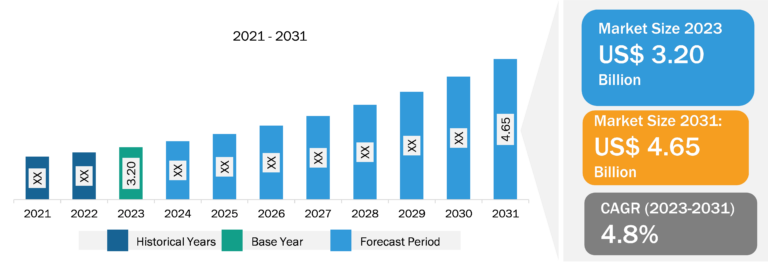

US Machine Control System Market

A machine control system integrates computers, sensors, and communication networks to enable automated machine operation. The machine control system assists the machine operator in achieving the target plane easily and quickly in earthwork operations. The machine control system calculates the position of the instrument on a piece of machinery, including the blade of a bulldozer or the bucket of an excavator, via a display and allows the machine operator to identify the exact operation plane. Further, many companies are focused on introducing numerous advancements in the automation industry. A machine control system is integrated with hydraulics in order to automate operations. This is predominantly helpful on the site, where operators are building complex grades and site profiles. For instance, with the Leica Geosystems machine control system, earthmoving equipment operators can finish jobs in 25–75% less time. These results also vary based on the job site, machine type, and type of materials used during operations. Machine control systems are becoming the standard on an extensive range of earthmoving equipment, including dozers, graders, excavators, loaders, scrapers, and rollers. Thus, the rising utilization of machine control systems to streamline earthwork operations fuels the US machine control system market growth.

A business ecosystem is a network of organizations, suppliers, distributors, customers, competitors, and others involved in delivering a specific product or service. Ecosystem analysis helps understand the steps adopted until the final product is prepared and a brief overview of stakeholders engaged in raw material procurement, manufacturing, and end use. Key stakeholders in the US machine control system market ecosystem include component providers, manufacturers, distributors/suppliers, and end use industries.

Component Providers:

Component providers offer production machine control system manufacturers with sensors, motors, actuators, and other necessary infrastructure components. Component providers play a crucial role in the quality and availability of the final product, and their operations impact the overall supply chain. Companies in the industry are actively involved in partnerships with component providers to establish an infrastructure for machine control systems. Fluctuations in the price of components can impact the cost of production and the cost of the machine control system.

Manufacturers:

Manufacturers develop different types of machine control systems to meet the requirements of end use industries. Manufacturers also test machine control systems to fulfill the required specifications. They also play a vital role in providing training, customer support, and troubleshooting. Topcon Corp., Trimble Inc., Hemisphere GNSS Inc., Komatsu Ltd., Schneider Electric SE, Leica Geosystems AG, Andritz AG, and M-Tech Control Corp. are among the key players operating in the market.

Distributors or Suppliers:

Manufacturers can directly supply machine control systems to end use industries or seek suitable distributors or suppliers to supply the product for various applications. The distributors or suppliers usually help them effectively reach the target customers. They might offer their products through independent dealers operating across different regions. In some instances, manufacturers directly sell their products to end use industries. Distribution might involve warehouses, logistics providers, and transportation networks to ensure timely delivery and efficient inventory management.

End Use Industries:

End use industries of machine control systems include Infrastructure, commercial, residential, industrial, and others. Machine control systems are used to guide excavators, dozers, graders, and compactors to create smooth, accurately leveled surfaces ready for final paving.

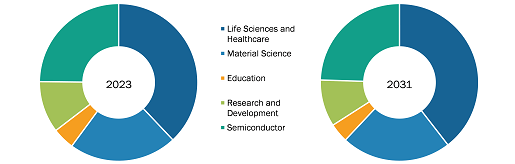

Segmental Overview

The “US machine control system market analysis” has been carried out by considering the following segments: type, equipment, industry, view type, and type of delivery. In terms of type, the market is segmented into total stations, GNSS, laser scanners, airborne systems, GIS collectors, and others. Based on equipment, the market is segmented into excavators, graders, loaders, dozers, scrappers, paving systems, and others. In terms of industry, the market is categorized into infrastructure, commercial, residential, and industrial. Based on view type, the market is bifurcated into 2D and 3D. In terms of type of delivery, the market is bifurcated into retrofit and OEM build.

Based on industry, the infrastructure segment held the largest US machine control system market share in 2022 and industrial segment is expected to grow with the highest CAGR in the forecast period. Several factors drive the adoption of machine control systems in the infrastructure industry. The need for safety measures in construction sites has led to the introduction of machine control systems to improve worker safety and reduce accidents. Also, the growing demand for infrastructure development, driven by population growth and urbanization, has increased the need for efficient and precise construction methods. Machine control systems enable better control over construction processes, resulting in improved quality and reduced project timelines. Infrastructure projects such as the construction of roads, highways, bridges, railways, airports, dams, and other public works. Machine control systems are utilized in these projects to enhance precision, efficiency, and productivity. They enable accurate positioning, guidance, and control of machinery such as excavators, loaders, graders, and other equipment used in infrastructure construction. Thus, wide use and need of machine control system in the infrastructure segment fuels the segment’s growth in US machine control system market forecast.

Modern industrial processes rely heavily on machine control systems. These systems are intended to regulate machine movement, speed, and function in a variety of industrial and production applications. One of the most significant advantages is their potential to increase the efficiency and productivity of industrial processes. Businesses can eliminate the demand for manual labor while improving the consistency and precision of their processes by automating machine control. Moreover, in September 2023, Leica Geosystems launched the Leica MC1 3D machine control system with Caterpillar factory-installed NGH sensors. Product launches such as these helps industrial processes run smoothly, further boosting the adoption of machine control system for the industrial purpose and propelling the US machine control system market.

Based on view type, the 2D segment held the largest US machine control system market share in 2022 and 3D segment is expected to grow with the highest CAGR in the forecast period.

The 2D view type of display has various applications, such as planning projects, communicating ideas, and ensuring work is executed without any errors. Several players in the market are launching their 2D models which is fueling the US machine control system market. For instance, in September 2019, Volvo Construction Equipment announced the creation of an integrated Trimble Earthworks Grade Control Platform for Volvo Dig Assist 2D machine control system as a result of a three-year partnership with Trimble Inc.

3D models are built using modern computer programs and data from light detection and ranging (LIDAR) technology, the global positioning system (GPS), and aerial photogrammetry. In addition to the functions of 2D modeling, 3D models can contain a wide variety of information types and can be used for site layout, grading, and other purposes. Moreover, while expanding the portfolio of machine control systems, several market players have launched 3D machine control systems. For instance, in February 2022, Hitachi Construction launched 3D machine control excavators. Thus, such product launches propel the US machine control system market growth.

Market Analysis: Competitive Landscape and Key Developments

Topcon Corp, Trimble Inc, Hemisphere GNSS Inc, Komatsu, Schneider Electric SE, MOBA MOBILE AUTOMATION AG, Leica Geosystems AG, ANDRITZ, M-Tech Control Corp, and AB Volvo are among the prominent players profiled in the US machine control system market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The US machine control system market report provides detailed market insights, which help the key players strategize their growth.