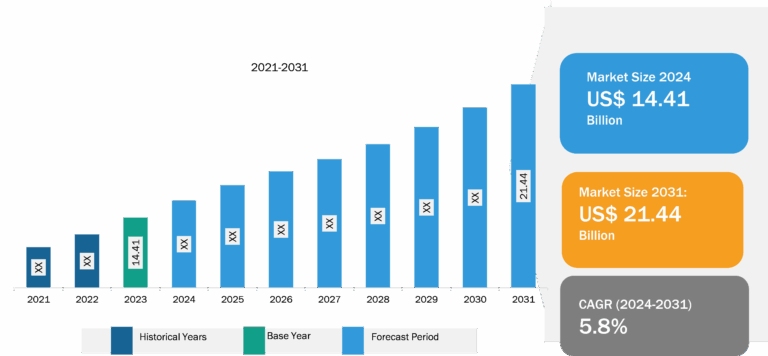

US and Europe Cell and Gene Therapy Manufacturing Services Market

Cell & gene therapy (CGT) programs are rapidly advancing from research & development to clinical trials and commercial approval. Additionally, cell and gene therapy comprise the next generation of life-enhancing and curative therapies. With therapies experiencing new approvals, the demand for skilled professionals in cell and gene therapy manufacturing services will rise. The increase in number of approvals of cell and gene therapies and increasing popularity of outsourcing cell and gene therapy manufacturing are fueling the US and Europe cell and gene therapy manufacturing services market size. However, high cost of cell and gene therapy manufacturing hinders the US and Europe cell and gene therapy manufacturing services market growth.

Automation of Cell and Gene Therapy Manufacturing Services Fuels the US and Europe Cell and Gene Therapy Manufacturing Services Market Growth

Incorporating automation in cell and gene therapy manufacturing would lead to a reduced risk of contamination, improved consistency, and decreased cost of production. Lonza Cocoon and the CliniMACS Prodigy system from Miltenyi are a few of the devices available in the market to enable automation. These products have been designed to enable the automation of most sequential unit operations for a CAR-T process within a single system. The rising demand for cell and gene therapies has shifted the production of cell and gene therapy products from a small-volume process to a large-volume process. In addition to the increasing research activities, the evolution of cell and gene therapy from an academic and clinical setting to mass production and commercialization has propelled the demand for automation in commercial manufacturing.

In July 2020, Thermo Fisher Scientific Inc. and Lyell Immunopharma partnered to develop and manufacture processes to design effective cell therapies for cancer patients. Under this partnership, the companies aim to improve the capability of T-cells and support the development of an integrated current good manufacturing practice (cGMP) compliant platform (system and software), along with reagents, consumables, and instruments. Further, government agencies are adopting automation in the manufacturing of cell therapies to increase the national production capabilities of the country. For instance, as of March 2023, the UK Stem Cell Bank of the Medicines and Healthcare Products Regulatory Agency (MHRA) was testing automated robotic technology for developing stem cell technology for the manufacturing of stem cell-based therapies. Thus, automation is emerging as a new trend in the US and Europe cell and gene therapy manufacturing services market.

Companies operating in the cell and gene therapy manufacturing services market focus on strategic developments such as collaborations, expansions, agreements, partnerships, and new product launches, which help them improve their sales, expand their geographic reach, and enhance their capacities to cater to a larger than existing customer base. A few of the noteworthy developments in the cell and gene therapy manufacturing services market are mentioned below:

• In May 2023, Lonza launched the TheraPEAK T-VIVO Cell Culture Medium with a novel chemically defined formulation devised to optimize and streamline CAR T-cell manufacturing. The TheraPEAK T-VIVO Cell Culture Medium can exhibit a high performance without the need to add human serum or its components, unlike other serum-free media.

• In October 2022, Pfizer Inc. completed the acquisition of Biohaven Pharmaceutical Holding Company Ltd., the manufacturer of NURTEC ODT (rimegepant), an innovative migraine therapy approved for both acute treatment and prevention of episodic migraine in adults.

• In March 2022, Cellevolve Bio partnered with Seattle Children’s Therapeutics to develop and commercialize new multiplex CARs for paediatric cancers. Under the collaboration, the partners will focus on the BrainChild research program, a suite of five multiplex CARs, to treat pediatric central nervous system (CNS) malignancies. In partnership, they would leverage the Seattle Children’s Cure Factory facility to conduct early clinical GMP research on new CARs.

Therefore, introducing products such as viral vectors, media for cell therapy manufacturing, and allogeneic T-cells; the development of innovative products targeting various health issues to create new or improved products; and the initiation of new businesses to remain competitive in the market can help speed up the development of new platforms for cell and gene therapy manufacturing services. Thus, these strategic initiatives create significant opportunities for the US and Europe cell and gene therapy manufacturing services market growth.

US and Europe Cell and Gene Therapy Manufacturing Services Market: Competitive Landscape and Key Developments

Thermo Fisher Scientific Inc, Merck KGaA, Charles River Laboratories International Inc, Lonza Group AG, WuXi AppTec Co Ltd, Catalent Inc, Takara Bio Inc, Nikon Corp, FUJIFILM Holdings Corp, National Resilience Inc, and Oxford BioMedica Plc are a few key companies operating in the US and Europe cell and gene therapy manufacturing services market. These companies adopt product innovation strategies to meet evolving customer demands, which allows them to maintain their brand name in the US and Europe cell and gene therapy manufacturing services market.

A few of the recent developments in the US and Europe cell and gene therapy manufacturing services market are mentioned below:

- In October 2022, Thermo Fisher Scientific Inc. unveiled the Gibco CTS DynaCellect Magnetic Separation System help cell therapy developers easily move from the process and clinical development to commercial manufacturing. This next-generation cell isolation, cell activation, cell depletion, and Dynabeads magnetic beads removal instrument provides a scalable, flexible, automated, and closed system to help optimize the cell therapy manufacturing process.

- In June 2022, National Resilience, Inc. and The University of Texas MD Anderson Cancer Center launched a joint venture, the Cell Therapy Manufacturing Center (CTMC), to accelerate the development and manufacturing of innovative cell therapies for patients with cancer. The joint venture advances its work within a culture of academic innovation and industrial expertise. The joint venture engages with MD Anderson researchers and external industry collaborators to advance new therapies through preclinical and clinical development.