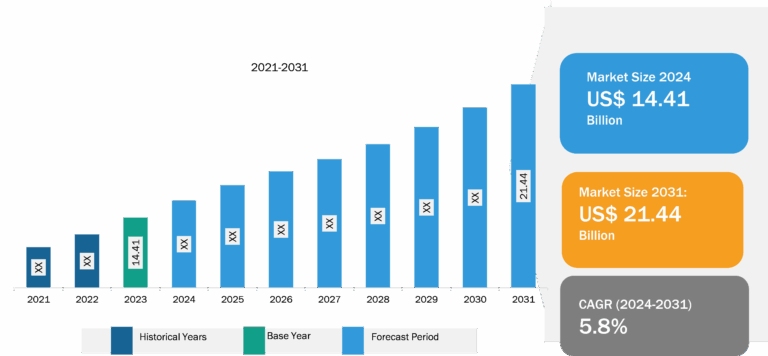

Logistics Automation Market

Adoption of Industry 4.0 across the manufacturing industry is facilitating the expansion of the logistics automation market size. With technological advancements, the adoption of automated machines across various industries is gaining high momentum, especially in the manufacturing & retail industry. The acceptance of automation in this industry has helped reduce human errors. The manufacturing & retail industry is continuously focusing on reducing total operational costs by eliminating human interference in operations. Autonomous vehicle providers are focusing on developing autonomous vehicles and truck platooning, which integrates advanced connectivity technology and automated driving support systems to provide efficient logistics services to its customers. These autonomous vehicles automatically maintain a close distance between several trucks, which connect with each other for short journeys. The truck at the start of the platoon is the front-runner, and the vehicles behind it adapt and react to variations in its movement, and the truck does not require action from drivers. Truck platooning holds a huge potential to make road journeys safer, cleaner, and more efficient. For instance, Scania, a developer of autonomous vehicles, is focusing strongly on semiautonomous platoons where the driver handles a main truck and monitors a train of unmanned follower trucks.

Europe Logistics Automation Market

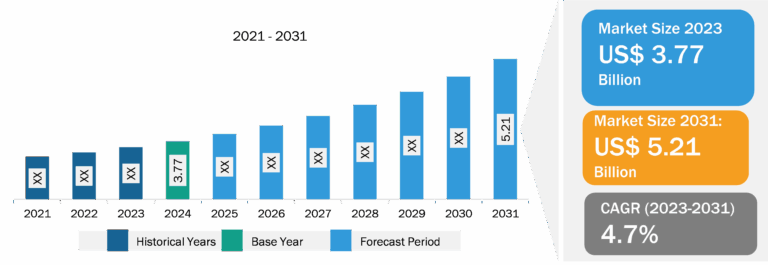

The Europe logistics automation market is segmented into Germany, the UK, France, Russia, Italy, and the Rest of Europe. In Europe, the rise in automation is one of the factors driving the logistics automation market growth. Also, constant growth in internationalization is anticipated to provide a considerable rise in opportunity for industry players in this region. This region’s highly outsourced logistics services are inventory management, transportation, and warehousing. There is a rise in investment activities in Europe to strengthen the logistics automation market. For instance, according to Bnp Paribas Real Estate, the investment in industrial and logistics rose by 51% in 2021 compared to 2020, with US$ 77.39 billion (EUR 65 billion) in investments. In addition, the investment rose to over US$ 30 billion in the first half of 2022. Thus, the growing investment for efficient management in the logistics market will propel the growth for warehouse management systems during the forecast period. This creates the opportunity for the growth of logistics automation market share to meet consumer demand on time.

The Europe logistics automation market is witnessing remarkable growth in industrial and automobile applications. The presence of large automobile manufacturing industries in Germany has fueled the demand for trade, transportation, and logistics in the country. Furthermore, economically strong countries, such as the UK, Italy, and Spain, are observing significant development in the implementation of logistics automation solutions for the optimization of supply chains across various end-use sectors, such as healthcare, retail, e-commerce, automobile, and food & beverages, across the region.

Moreover, governments of various countries are investing in automating manufacturing businesses and their business operations in the region. For instance, in July 2021, the UK government announced an investment of US$ 59.3 million (GBP 53 million) to drive the development of digital manufacturing technologies. Out of which, US$ 28.10 million (GBP 25 million) will be invested in setting up five new industry-sponsored research centers to accelerate the development of cutting-edge digital solutions that can transform manufacturing businesses. The remaining amount will be invested in a digital supply chain innovation hub and will also be provided to 37 individual projects to digitalize and transform manufacturing supply chains. Moreover, Germany’s High-Tech Strategy 2025 (HTS), a German R&D and innovation program, aims to use technological change and research and innovate on topics such as human-robot collaboration. The German government is investing US$ 345 million for five years, which is ~US$ 69 million annually, until 2026 to provide solutions for the more flexible organizing of work processes or the support of mobile work. Thus, the growing government support to boost automation will further boost logistics automation market growth.

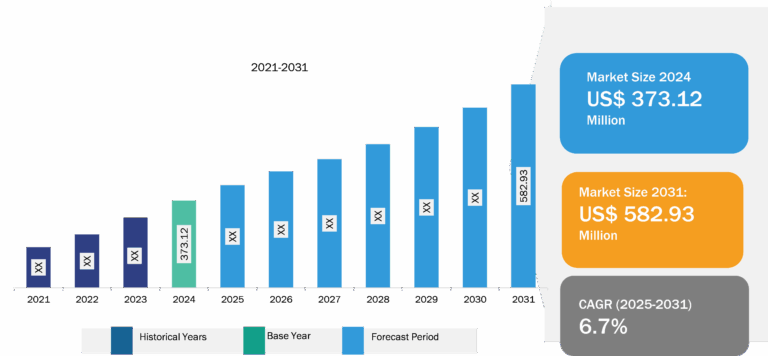

Segmental Overview

The logistics automation market analysis has been carried out by considering the following segments: component, mode of freight transport, application, and end-user industry. Based on component, the logistics automation market is segmented into hardware, software, and services. Based on mode of freight transport, the logistics automation market is segmented into land, water, and air. Based on application, the logistics automation market is segmented into warehouse management and transportation management. Based on end-user industry, the logistics automation market is segmented into manufacturing, retail and e-commerce, oil and gas, food and beverages, automotive, healthcare and pharmaceutical, and others.

Based on mode of freight transport, the logistics automation market is segmented into land, water, and air. Transportation is one of the essential services included in the logistics operations. Efficient transportation involves physically moving deliveries in the relatively right conditions, at the right time, and in a cost-effective manner. Freight transport is the movement of goods from the manufacturing site or storage site to the distribution site. Based on mode of freight transport, the global logistics automation market is segmented into air, road, and sea. In land transport, vehicles are owned or managed by a third party, and transportation operations adhere to licensing, insurance, and vehicle regulations.

Market Analysis: Competitive Landscape and Key Developments

- In 2023, Manitou Group opened a new automated warehouse at its spare parts center in Ancenis. The innovative solution consists of the Shuttle System from Mecalux.

- In 2023, Daifuku Co. Ltd significantly expanded its footprint in India through its subsidiary, Daifuku Intralogistics India Private Limited. This expansion includes the acquisition of Hyderabad-based Vega Conveyors & Automation in 2019, followed by a consolidation of operations and rebranding in 2022.