Middle East and Africa Factory Automation Market

Demand for Soft-PLC to Fuel Middle East and Africa Factory Automation Market Growth During Forecast Period

SoftPLCs are software-based versions of programmable logic controllers (PLCs). It offers the combination of the functions of conventional PLCs with data loggers, communication gateways, and additional components, including human-machine interfaces (HMIs), SCADA systems, motion control, and web servers. In recent years, the demand for SoftPLCs has increased significantly across a wide range of industrial applications, including manufacturing, energy, factory automation, packing, building products and materials, semiconductors, and others. PLCs play a major role in industrial automation systems, offering control and monitoring capabilities for a wide range of processes. Security and safety are a major concern with any automation system, which increases the demand for SoftPLCs to fulfill the safety and security needs of industries.

In the MEA, many manufacturers demand SoftPLC technology to create a resilient, safe, and secure solution. The growing demand for SoftPLCs in a variety of industrial applications encourages market players to develop and advance their existing product portfolio to attract customers from numerous industries. A few of the recent developments made by SoftPLC manufacturers are listed below:

• In February 2024, WEG S.A. launched the PLC410 programmable logic controller. The PLC500 is a technologically advanced PLC integrated with CODESYS programming software. This new controller is a highly versatile industrial automation solution that is primarily used in packaging machines, labelers, filling machines, and other applications. Further, this SoftPLC offers greater cost-effectiveness, combining high performance in hardware with an advanced programming logic development platform, which increases its demand in a variety of industries, including pulp & paper, metallurgy, pharmaceuticals, and food & beverages, among others.

• In May 2023, Siemens AG launched SIMATIC S7-1500 PLC, which allows a more flexible and modular design of production plants. SIMATIC S7-1500 PLC is a virtual PLC (vPLC) integrated with software to be managed centrally with the Industrial Edge Management system. Virtual PLCs can also help with Information Technology (IT) and Operational Technology (OT) (IT-OT) integration. IT-OT convergence is developing across industries. The close integration of IT and OT enables plants to make better data-driven decisions related to performance, efficiency, flexibility, and sustainability while also ensuring stronger plant security.

The expansion of numerous industries in the MEA, such as manufacturing, packaging, semiconductors, etc., increases the demand for SoftPLCs for securely and safely managing factory operations. As a result, the demand for cost-efficient, safe, secure, flexible, and versatile SoftPLCs to automate factory processes is increasing. Thus, rising awareness related to the significant benefits provided by SoftPLCs is expected to create opportunities for the MEA factory automation market growth during the forecast period.

Middle East and Africa Factory Automation Market: Industry Overview

The Middle East and Africa Factory Automation market analysis has been carried out by considering the following segments: component and industry vertical. Based on component, the Middle East and Africa factory automation market is bifurcated into hardware and software. The hardware segment is further segmented into PLC, industrial PC, valves and valve system, cylinder and actuator, air preparation, vacuum technologies, and sensors. The software segment is subsegmented into SCADA, MES, and others. The hardware segment held a larger Middle East and Africa factory automation market share in 2023. On the basis of industry vertical, the Middle East and Africa factory automation market is segmented into automotive, food & beverages, packaging, manufacturing, mining, metals, pulp & paper, life science & pharma, cement, glass, transportation, infrastructure, power, and others. The others segment is further segmented into agriculture, water, and renewables. The manufacturing segment held the largest Middle East and Africa factory automation market share in 2023.

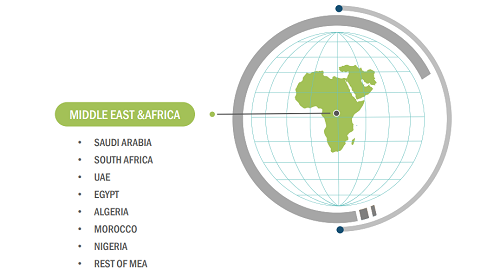

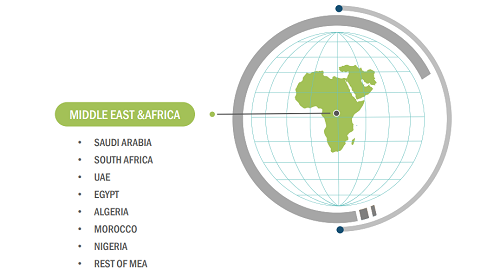

The Middle East and Africa Factory Automation market is segmented into the Saudi Arabia, UAE, Egypt, South Africa, Nigeria, Algeria, Morocco, and Rest of Middle East and Africa. The factory automation market in the Middle East & Africa is segmented into South Africa, Saudi Arabia, the UAE, Algeria, Nigeria, Egypt, Morocco, and the Rest of Middle East & Africa. The above countries in the region are highly automating their factories to improve manufacturing operations. The Ministry of Industry and Mineral Resources has taken the Future Factories Program Initiative to automate ~4,000 factories in Saudi Arabia. The program intends to transit 4,000 factories toward the adoption of the fourth industrial revolution, automation, and sophisticated industrial technologies that further enhance operational efficiency and manufacturing capabilities. Moreover, the government of Saudi Arabia is taking initiatives toward the adoption of industrial robots. For instance, according to Telecommunications and Digital Government Regulatory Authority (TDRA) data, The Dubai Robotics and Automation (R&A) Program intends to boost the robotics sector’s contribution to 9% of Dubai’s GDP before 2032. As part of the initiative, 200,000 robots will be provided over the following ten years until 2032. This raises the efficiency and productivity in a variety of industries, including logistics, and transportation, among others. Thus, significant government initiatives towards factory automation are leading to the growth of the MEA factory automation market.

Middle East and Africa Factory Automation Market: Competitive Landscape and Key Developments

Rockwell Automation Inc, Siemens AG, OMRON Corp, Mitsubishi Electric Corp, Schneider Electric SE, Delta Electronics Inc, Inductive Automation LLC, Honeywell International Inc, SMC Corp, CKD Corporation, Airtac International Group, IMI Plc, Parker Hannifin Corp, Festo SE & Co. KG, and AVEVA Group Plc are among the key players profiled in the Middle East and Africa factory automation market report. Several other essential market players were analyzed for a holistic view of the market and its ecosystem.

The Middle East and Africa factory automation market report provides detailed market insights, which help the key players strategize their market growth. A few recent developments by the key players, as per company press releases, are mentioned below.

- In June 2024, Rockwell Automation, Inc. (NYSE: ROK), the world’s largest company dedicated to industrial automation and digital transformation, announces further collaborations with NVIDIA to supercharge the development of safer and smarter industrial AI mobile robots. Earlier this year, Rockwell announced its ongoing work with NVIDIA to increase the scale and scope of AI in manufacturing. The collaboration is now expanding to involve robotics, helping drive the use of AI in autonomous mobile robots (AMRs) to improve performance and efficiency. Rockwell brings AMRs and production automation applications to industrial customers who are looking for increased efficiencies in their factories. This will help unlock unrealized potential in this space via the integration of the NVIDIA Isaac robotics platform.

- In May 2024, Siemens, a leading technology company, today announced a breakthrough in the longstanding challenge of closely managing numerous hardware control points throughout the factory. The solution is the new Siemens Simatic Automation Workstation, which allows manufacturers to replace a hardware PLC, a conventional HMI and an edge device with a single, software-based workstation. This ushers in Information Technology (IT) workflows to Operational Technology (OT) environments.