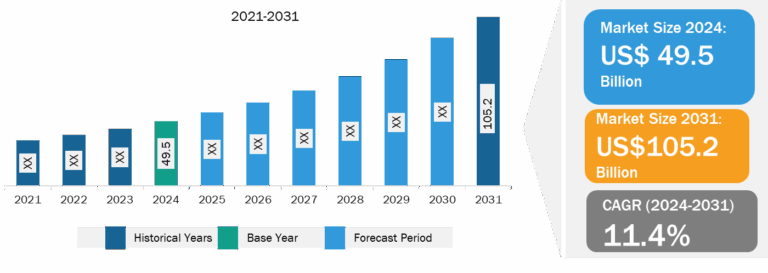

Antistatic Brushes Market

In 2022, Asia Pacific held the largest share of the global antistatic brushes market. According to the International Organization of Motor Vehicle Manufacturers (OICA), Asia-Oceania’s vehicle production increased from 46.8 million in 2021 to 50.0 million in 2022. The development of automotive parts and components in the region with the rise of electric vehicle production will create lucrative opportunities for antistatic brushes. Extensive innovation and prototyping from major automakers is the major factors driving the market. Further, electronics and semiconductor manufacturing businesses in Asia Pacific have been a major driver of global trade. Asia Pacific is a global hub for the production and exports of technical consumer goods (TCG), including consumer electronics such as laptops & computers, cellphones, radio sets & sound systems, and televisions, as well as other essential electronic parts and small & big domestic appliances. According to the Association of Southeast Asian Nations, the electronics sector accounts for 20–50% of the total value of export of most countries in Asia. All these factors are propelling the antistatic brushes market growth in Asia Pacific.

Advancements in 5G, Nanotechnology, 3D printing, and Other Technologies to Bring New Trends in Market

According to Viavi Solutions Inc.’s report, over 92 countries across the world have launched 5G networks. A further 23 countries have pre-commercial 5G network trials underway, and 32 nations have announced their 5G rollout plans. The widespread rollout of 5G networks has led to an increased demand for smartphones and other consumer electronics products. With this, the production levels of electronic components—including integrated circuits, transceivers, antennas, and printed circuit boards—have also upsurged. These components are often small, delicate, and sensitive to static electricity. Antistatic brushes are crucial for handling and protecting these components during the manufacturing process, ensuring their reliability and performance. Antistatic brushes have traditionally been in use in electronics manufacturing, automotive, and printing industries. However, the emergence of new industries is resulting in the expansion of the application scope of antistatic brushes. For instance, the growing field of 3D printing and additive manufacturing can use antistatic brushes to mitigate static charges during printing, thus improving the quality of printed parts. Similarly, developing flexible electronics, wearable devices, and IoT devices open up new avenues for artistic brush applications.

Antistatic Brushes Market: Segmental Overview

Based on filament material, the antistatic brushes market is segmented into nylon, stainless steel, brass, aluminum, carbon fiber, and others. The stainless steel segment held the largest market share in 2022. This material is resistant to abrasions and can be subjected to continuous mechanical load. Stainless steel filaments also have a wide range of applications, such as high-speed paper, printers, conveyors, continuous testing, hazardous operations, welding, and high-temperature operations.

Based on brush type, the antistatic brushes market is segmented into tufted strip and plate brushes, disk brushes, cylindrical brushes, and others. The tufted strip and plate brushes segment held the largest market share in 2022. Tufted brushes are used to sort, move, and position goods, and to reduce damage to products in pharmaceutical packaging and other processes. Tufted brushes and plate brushes also find applications in creating conductive and non-conductive environments, and in cleaning and protecting machinery. Tufted strip and plate brushes are highly used in industries such as automotive, ceramics, electronics and electrical, food & beverage, medical, pharmaceutical, printing, and glass manufacturing, labeling.

Based on application, the antistatic brushes market is segmented into automotive, metalworking, electronics, industrial machinery, and others. The industrial machinery segment held the largest market share in 2022. Industrial machinery is one of the major application sectors of antistatic brushes. These brushes are highly used in luggage wrapping machines, packaging machines, laminating machines, printing machines, labeling and coding machines, slitting machines, etc.

Impact of COVID-19 Pandemic on Antistatic Brushes Market

Governments of various countries across the world imposed country-wide lockdowns that directly impacted the growth of the industrial sector. In China, movement restrictions and related labor shortages reduced industrial activities across various industries. The governments of various Asia Pacific economies took steps to restrict the spread of SARS-CoV-2 by announcing countrywide lockdowns, which negatively impacted the growth of industrial sectors and lowered the demand for antistatic brushes. Manufacturing facilities in Asia Pacific had to implement new protocols and restrictions to comply with social distancing measures and ensure employee safety. This resulted in decreased production capacity and efficiency in antistatic brush manufacturing facilities, impacting their availability in the market. According to the US International Trade Commission (USITC), the automotive industry is highly vulnerable to the pandemic, and vehicle sales in the US decreased by 15% from 2019 to 2020. In 2020, disruptions in manufacturing facilities and the shortage of raw materials led to a reduction in the demand for antistatic brushes in North America.

Various industries began to revive with the resumption of operations in 2021, which triggered the demand for antistatic brushes. Moreover, manufacturers could operate at full capacities, which helped them overcome demand–supply gap challenges. These factors created conducive conditions for the progress of the antistatic brushes market.

Antistatic Brushes Market: Competitive Landscape

A few of the players operating in the global antistatic brushes market include Gordon Brush Mfg Co Inc, The Industrial Brush Co Inc, Precision Brush Co, Cocker-Weber Brush Co, Spiral Brushes Inc, Amstat Industries Inc, Ultrafab Inc, KOTI Industrial and Technical Brushes BV, Westmont Inc, and KIST + ESCHERICH GmbH. Players operating in the antistatic brushes market focus on providing high-quality products to fulfill customer demand.