Metal Casting Market

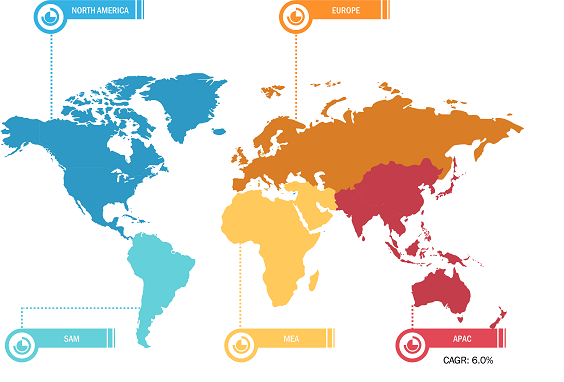

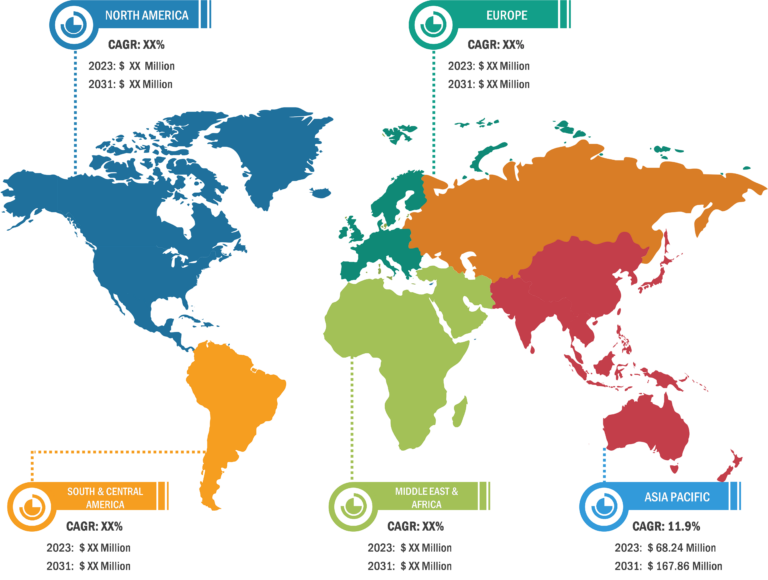

In 2022, Asia Pacific held the largest share of the global metal casting market and is expected to account for highest growth rate over forecast period. The demand for metal casting is directly proportional to the region’s rapid industrialization. Therefore, the large number of manufacturing industries across the region is expected to boost the demand for metal casting during the forecast period.

Rising Demand for Industrial Machineries

Industrial machinery enhances the productivity of manufacturing operations and positively impacts industrial competitiveness. As per the data released by The Observatory of Economic Complexity (OEC), China was the top exporter of industrial machinery in 2021, with exports valued at US$ 1,540 billion. As per the International Trade Administration, in 2021, the US exported machinery worth US$ 44 billion and electrical machinery worth US$ 24 billion. According to the Germany Trade & Invest, the machinery & equipment sector was the second largest industry in Germany in 2021. The sector in the country comprises 6,600 companies. The revenue generated by the sector is expected to increase from US$ 243.3 billion in 2021 to US$ 319.2 billion by 2025. According to UCIMU-Sistemi Per Produrre, the production of machine tools, robots, and automation systems reached ~US$ 8 billion in 2022, an increase of 15% compared to 2021. The use of machine tools rose by 26% in 2022 compared to 2021, specifically driven by deliveries to the domestic market.

As per the Parker Hannifin Corporation report, the global market for computer numerically controlled (CNC) machine tools is projected to reach US$ 129 billion by 2026. According to the US Plastics Industry Association, the shipments of injection molding and extrusion machinery rose by 19.3% in the fourth quarter of 2020, compared to the same period in 2019, in North America. A press release by the International Federation of Robotics in 2022 stated that car and car component manufacturers accounted for 47% of robot orders in North America in Q1 2022, a rise of 15% year-on-year. Industrial machinery performs diverse operations, from material handling, assembly, and welding to finishing and palletizing applications. Metal castings are widely used in the production of bearing housing machine tools and components and machinery frames and bases. Also, they are used for structural support. Thus, rising demand for industrial machinery propels the growth of the metal casting market across the globe.

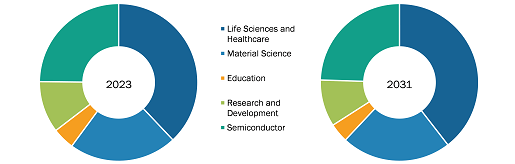

Metal Casting Market: Segmental Overview

Based on product type, the metal casting market is segmented into carbon steel alloys, stainless steel alloys, aluminum alloys, grey iron, ductile iron, and others. The grey iron segment held the largest market share in the global metal casting market in 2022 and is anticipated to account for the highest CAGR during the forecast period. Also, ductile iron casting is created by pouring molten ductile iron into a mold and allowing it to cool for solidifying into a specific shape. Due to its high strength, good machinability, fatigue strength, and higher modulus of elasticity, ductile iron is used in a wide range of applications such as valves, pump bodies, crankshafts, gears, automotive, and other machine components.

Based on process, the metal casting market is segmented into sand casting, investment casting, gravity die casting, and others. The sand casting segment accounted for the largest market share in the global metal casting market in 2022 and is anticipated to account for the highest CAGR during the forecast period. Investment casting is another attractive segment in the global metal casting market. Investment casting is an expensive and labor-intensive process; it is used for mass production or in complex castings to produce metal casting products such as gears, bicycle trunks, moto discs, and spare parts in blasting machines.

Based on application, the metal casting market is segregated into automotive, aerospace, marine, textile, building and construction, oil and gas, industrial machinery, and others. The automotive segment accounted for the largest market share in the global metal casting market in 2022. The industrial machinery segment is anticipated to record the highest CAGR during the forecast period. Metal casting is used to create metal components for many applications across manufacturing & assembly, agriculture, and other industries. It is also used in industrial pumps and commercial air compressors.

Impact of COVID-19 Pandemic on Metal Casting Market

In 2020, various industries had to slow down their operations due to disruptions in value chains caused by the shutdown of national and international boundaries. The COVID-19 pandemic caused supply chain disruptions in chemical & materials and hampered the growth of the metal casting market. The adverse effect of the pandemic on the manufacturing industry negatively impacted the demand for metal casting from this industry.

However, various economies have started reviving their operations. As a result, the demand for metal casting started increasing. The increasing use of metal casting in heavy industries is expected to offer more growth opportunities for the global metal casting market during the forecast period.

Metal Casting Market: Competition Landscape

ArcelorMittal SA, Posco Holdings Inc, Alcoa Corp, Lucchini RS SpA, RYOBI Aluminium Casting (UK) Ltd, Allard-Europe NV, FONDERIA AUGUSTA Srl, MEDEKO CAST Sro, Tycon Alloy Industries (Hong Kong) Co Ltd, and Novacast Ltd are a few of the key players working in the global metal casting market. A few major players operating in the global metal casting market are constantly focusing on various strategies such as investments in research & development activities.