Lignin Market

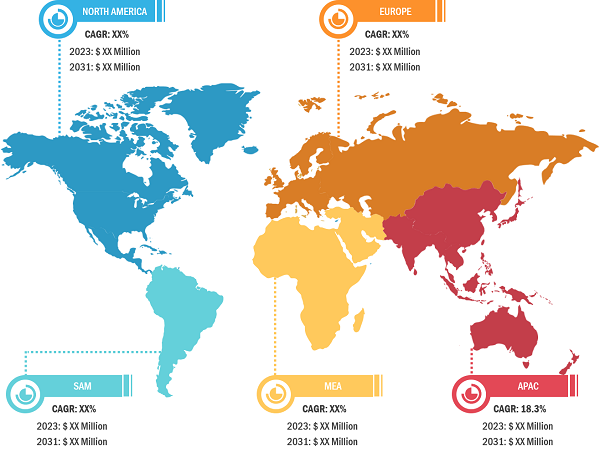

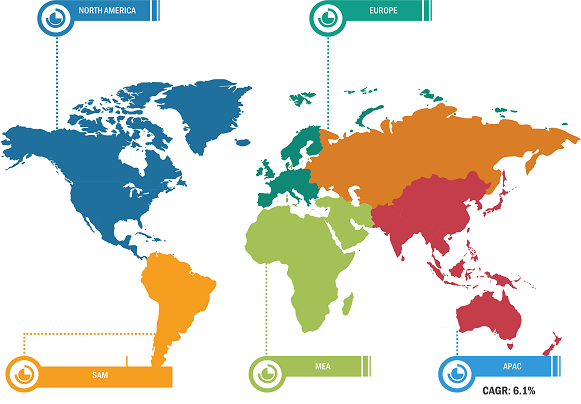

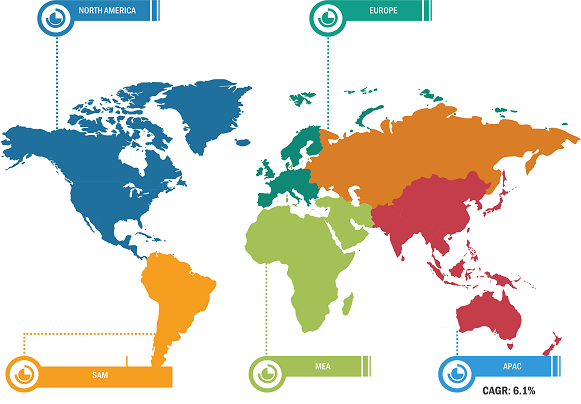

Asia Pacific is expected to register the highest CAGR in the lignin market during 2023–2031. China is one of the largest markets for lignin in the region. According to the report published by the International Trade Administration in 2023, water treatment facilities in China treated 98.1% and 28% of wastewater received from municipalities and rural areas, respectively, as of 2021. The government of China plans to build 80,000 km of sewage collection pipeline in the next few years. Policy support and investment focus would present significant opportunities in areas of black and odorous water bodies treatment, sewage pipeline maintenance, and wastewater treatment facilities construction in second and third-tier cities in the country.

Lignin-based adsorbents are extensively used in wastewater treatment processes for the adsorption of heavy metals, organic dyes, and drugs. They are also used as performance-modifying additives or fillers in the production of lignin-based thermoplastics. China has many major plastic and polymer manufacturers; these include Qingdao Xintongda Plastic Products Co Ltd, Suzhou Fansheng Plastic Manufacture Co Ltd, and Dongguan Xinhai Environmental-Friendly Material Co Ltd. According to a report published by the International Energy Agency in 2022, China was the largest cement producer in 2021, accounting for 55% of global production. Thus, developments in the water treatment industry and the progress of the polymer and concrete industries boost the demand for lignin in China.

In Europe, Sweden is projected to register the fastest CAGR from 2023 to 2031. The lignin market in Sweden is significantly growing owing to the rising awareness about its various applications. Lignin has lower purity and can also be extracted from waste produced by other industries such as biorefineries and pulp & paper. Due to its increasing demand, many companies are developing facilities for lignin commercialization in Sweden. For instance, in July 2024, ANDRITZ, the international technology group, was chosen by the Swedish forest industry group Södra to provide a complete system for kraft lignin production to its pulp mill in Mönsterås, Sweden. Södra is entering the lignin industry with this significant expenditure as part of its plan to maximize the amount of wood utilized in pulp production. This will be the largest kraft lignin plant globally and the first in Sweden for commercial use. Moreover, Lignin Industries AB, a Swedish greentech company, has created Renol, a bio-based material developed from lignin. Renol is used for industrial manufacturing of Polyethylene (PE), Acrylonitrile Butadiene Styrene (ABS), and Polypropylene (PP), which includes automotive, domestic goods, consumer electronics, and PE films.

Adoption of Lignin for Carbon Fiber Production to Boost Market Growth During Forecast Period

Carbon fibers are high-performance materials with superior properties such as high stiffness, high flexibility, good tensile strength, low thermal expansion, high-temperature tolerance, lightweight, and high fatigue resistance. These properties make carbon fibers essential in producing advanced composites for various industrial applications, including aerospace, transportation, wind energy, construction, and automotive. Most carbon fibers are manufactured from polyacrylonitrile, a petroleum-based, non-renewable, and unsustainable chemical at a relatively higher price. However, lignin is a renewable, inexpensive, and highly accessible resource that can fabricate lignin-based carbon fibers. The constant diminishing of petroleum resources and associated environmental issues are major factors expected to boost the demand for lignin for carbon fiber production. Manufacturers in the carbon fiber industry increasingly use lignin as a raw material to produce carbon fiber to cater to the increasing demand. For instance, in July 2021, Stora Enso Oyj, a manufacturer of pulp, paper, and other forest products, established a pilot plant for lignin-based carbon materials for batteries. According to Stora Enso Oyj, the demand for batteries is expected to rise tremendously over the next decade as battery producers require more sustainable materials for the electrification of mobility and reduction of carbon emissions. The company projects that carbon-based-anode materials, produced from converted lignin separated from wood, can be a more sustainable replacement for graphite-based battery anodes. Thus, the adoption of lignin for carbon fiber production is expected to increase in the coming years, fueling market growth.

Lignin Market: Segmental Overview

Based on form, the lignin market is segmented into solid and liquid. The solid segment held a larger market share in 2023, and it is expected to register a higher CAGR during the forecast period. Manufacturers in the lignin market provide lignin in the form of powder and granules for various end-use applications. Powdered and granular lignin is manufactured by drying lignin using a pre-drying method, followed by an additional drying process in a drying apparatus. These forms of lignin are largely preferred owing to various benefits such as ease of transportation, reduced water content, and good binder capability. Key players such as Borregaard AS, DOMSJö FABRIKER AB, Nippon Paper Industries Co Ltd, and Stora Enso Oyj offer powder and granular lignin. The powdered and granular form of lignin can be used in various applications such as concrete admixtures, activated carbon, and plastics and polymers, as it can be easily mixed while manufacturing different products.

Lignin Market: Competitive Landscape and Key Developments

Nippon Paper Industries Co Ltd, Borregaard ASA, Burgo Group SpA, Domsjo Fabriker AB, Sappi Ltd, Stora Enso Oyj, Suzano SA, The Dallas Group of America Inc, Tokyo Chemical Industry Co Ltd, and West Fraser Timber Co Ltd are among the prominent players profiled in the lignin market report. These market players focus on providing high-quality products to fulfill customer demand. They are also adopting strategies such as new product launches, capacity expansions, partnerships, and collaborations to maintain a competitive edge in the market.