Indexable Inserts Market

According to a new comprehensive report from The Insight Partners, the global indexable inserts market is observing significant growth owing to increasing use in metalworking and machining applications

The report runs an in-depth analysis of market trends, key players, and future opportunities. In general, the indexable inserts market comprises a vast array of inserts which are expected to register strength during the coming years.

Overview of Report Findings

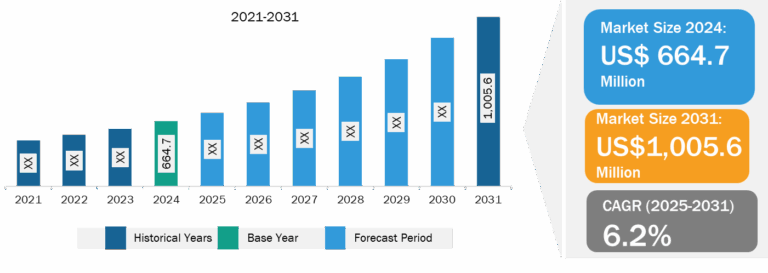

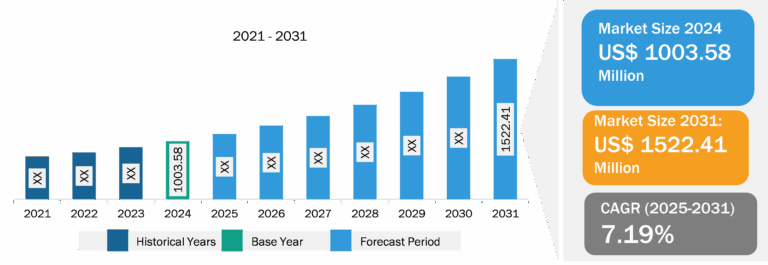

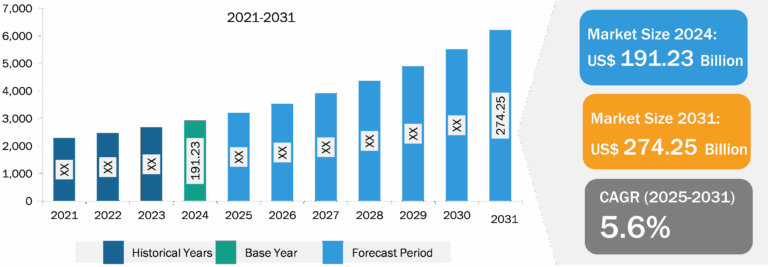

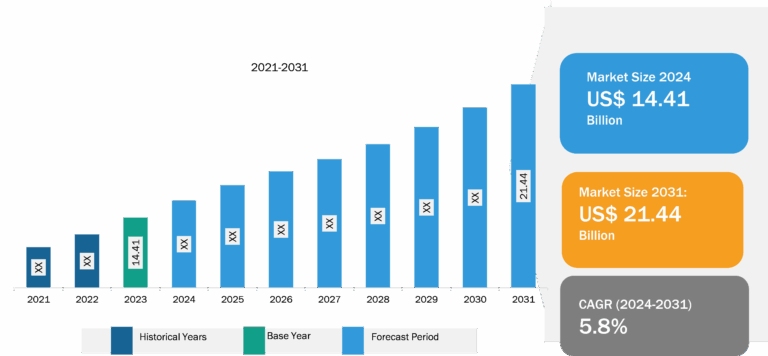

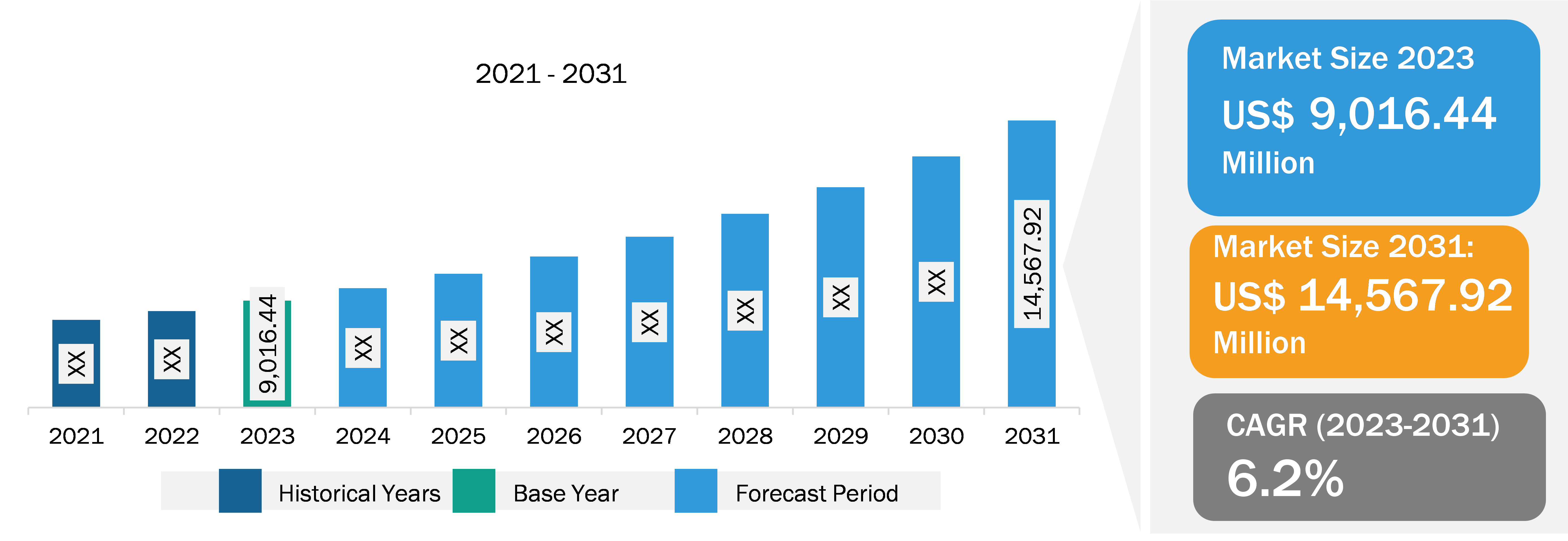

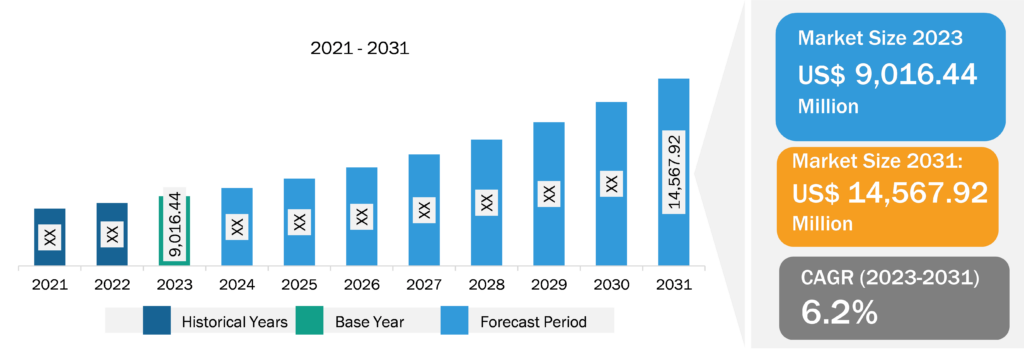

- Market Growth: The indexable inserts market is expected to reach US$ 14,567.92 million by 2031 from US$ 9,016.44 million in 2023, at a CAGR of 6.2% during the forecast period. Indexable inserts are an important component in modern machining and manufacturing and are revolutionizing the way tools are used in cutting, shaping, and finishing materials. These indexable inserts, also called replaceable cutting edges, are designed to be physically attached to a tool holder and allow for quick replacement without having to replace the entire tool. A typical insert has multiple edges, often three to eight, depending on the shape and design. If an edge is worn or damaged, the indexable insert can be rotated to a new edge, maximizing material utilization and reducing downtime. The indexable tool holder and insert are designed to provide a secure fit, with the insert sitting in the pocket of the holder and clamped tightly. This design ensures that the insert remains stable during machining and prevents movement that could affect precision and surface quality.

- Increasing Use in Metalworking and Machining Applications: Indexable cutting tools provide an efficient and cost-effective way to create complex shapes while maintaining accuracy and repeatability. These tools have become increasingly popular in recent decades due to their ability to quickly produce intricate shapes with minimal material waste. Their indexable cutting parts also make them extremely versatile and durable, making them an overall efficient choice for many machining tasks. By using indexable inserts, manufacturers can ensure projects are completed in less time while maximizing quality and efficiency. Hence, the increasing use of indexable inserts in metalworking and machining applications drives the market growth.

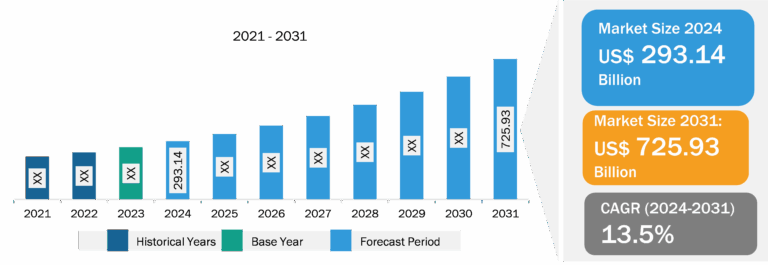

- Rising demand for Indexable Tools in Industrial Applications: Indexable inserts are increasingly used in industries such as automotive, aerospace, medical, and general manufacturing in various applications, including milling, drilling, grooving, and threading. Indexable inserts represent a significant advancement in cutting tool technology and offer numerous advantages over traditional tooling methods. Easy interchangeability, high performance, and versatility of cutting edges make indexable inserts indispensable in modern machining. Manufacturers can optimize their machining processes, improve productivity, and reduce costs by understanding the operating principles, benefits, and applications of indexable inserts. Automobile production is steadily increasing worldwide, especially in Asian and European countries, increasing the demand for indexable inserts. In the industry, indexable inserts are widely used in the metal machining of crankshafts, face milling and hole drilling, and other machining operations in producing auto parts.

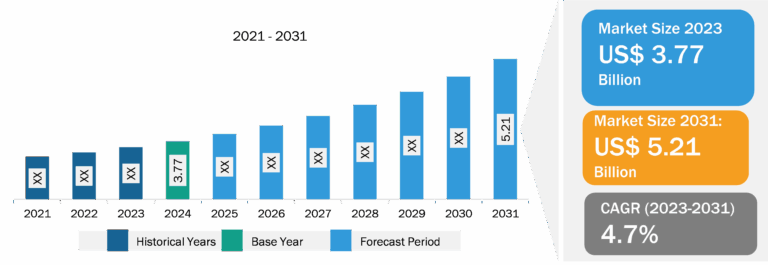

- Increasing Efforts to Improve Performance of Indexable Inserts with Utilization of Advanced Coatings and Materials: The focus on research and development of advanced coatings and materials that improve the wear resistance and performance of indexable inserts is expected to be the key future trend in the market. Innovations in nanotechnology and surface engineering are resulting in the development of coatings that improve tool life, reduce friction, and increase heat resistance, expanding the capabilities of machining tools. Coatings such as titanium aluminum nitride, titanium carbide, diamond-like carbon, and titanium nitride are widely used to provide indexable inserts with properties such as hardness, heat resistance, wear resistance, and corrosion protection.

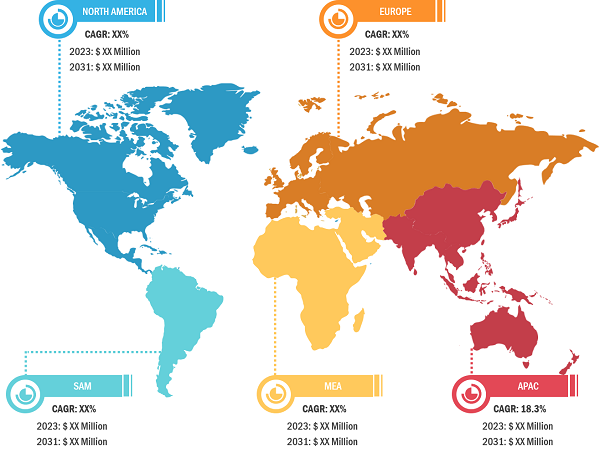

- Geographical Insights: In 2023, Asia Pacific led the market with a substantial revenue share, followed by Europe and North America. The indexable inserts market in North America is segmented into the US, Canada, and Mexico.

Market Segmentation

- The global indexable inserts market is segmented based on insert shape, application, size, insert material and industry.

- Based on insert shape, the indexable inserts market is segmented as round, square, triangle, rhombic and others.

- Based on application, the indexable inserts market is segmented into milling, drilling, turning, threading and others.

- Based on size, the indexable inserts market is segmented into upto 10 mm, 10-20 mm and above 20 mm.

- Based on insert material, the indexable inserts market is segmented into carbide, ceramic and composites, PCD inserts and others.

- Based on industry, the indexable inserts market is segmented into aerospace and defense, general industry, oil and gas, power generation, automotive, electric and electronics, medical and others.

- The indexable inserts market is segmented into five major regions: North America, Europe, APAC, Middle East and Africa, and South and Central America.

Competitive Strategy and Development

- Key Players: A few major companies operating in the indexable inserts market include Sandvik AB; Kennametal Inc.; Iscar Ltd.; Paul Horn GmBH; Kyocera Corporation; Ingersoll; Zhuzhou Cemented Carbide Cutting Tools Co., Ltd.; MITSUBISHI MATERIALS Corporation; Guhring, Inc.; YG-1 Co., Ltd.; Ceratizit Group; and Boehlerit GmbH & Co.KG.

- Trending Topics: Carbide Tools Market, End Mills Market

Global Headlines on Indexable Inserts

- “Kennametal Expands Its Product Portfolio with Three New Turning Products Launch”

- ” YG-1 Launches the New 4-Cutting-Edge Insert, YG TM4 MILL LNKU”

- ” YG-1 Expands i-Smart with Chamfer Type Modular Head in Metric Sizes”

- “Guhring extends its grooving and parting tool line-up”

Conclusion

Advantages provided by the indexable inserts include cost-effectiveness, improved efficiency, consistency and precision, versatility, and reduced downtime for the manufacturers. Indexable inserts are widely used in various industries, including automotive, aerospace, medical, general manufacturing, and energy and power, in manufacturing or machining processes such as milling, cutting, drilling, threading, turning, and grooving. Indexable inserts represent significant advancements in cutting tool technology and offer numerous advantages over traditional tooling methods. Easy interchangeability, high performance, and versatility of their cutting edges make indexable inserts indispensable in modern machining.

The report from The Insight Partners, therefore, provides several stakeholders—including component providers, pumps manufacturers and others—with valuable insights into how to successfully navigate this evolving market landscape and unlock new opportunities.