Robotic Welding Cell Market

The key players operating in the robotic welding cell market include Abb Ltd, Acieta LLC, Carl Cloos Schweisstechnik Gmbh, Kawasaki Heavy Industries, Ltd; Kuka AG; Phoenix Industrial Solutions; The Lincoln Electric Company; Wec Group Ltd.; Yaskawa America, Inc.; among others. In addition to the ten players that are profiled in the report, there are several other global, regional, and local players operating in the global robotic welding cell market ecosystem which were also studied during the course of the study to get a holistic view of the entire market.

Integration of Artificial Intelligence (AI) in Robotic Welding

Artificial intelligence (AI) and machine learning (ML) are being adopted in almost all industries, including the welding industry. By leveraging AI, welding systems can be made smarter and adaptable. Some of the key areas where AI integration is beneficial are weld defect detection, adaptive welding, and path planning. One of the key factors in the welding process is ensuring quality control. Defects in the welded area lead to high risks in the overall strength and safety of the final product. Integration of AI and ML, along with advanced vision systems, can be used for defect detection in real-time. This technology can be used to detect various types of defects, such as cracks, incomplete welding, and porosity. In addition, as this technology continuously gathers data from the system in real-time, AI and ML can learn and improve the process by analyzing real-time and historical data.

Another area where AI can be beneficial is adaptive welding. As of now, most of the welding factors, such as joint geometry, current, voltage, and travel speed, are adjusted manually. By adopting AI technology, all these welding factors can be optimized by the technology in real-time. Owing to the factors mentioned above, many technology providers and robotic welding cell manufacturers are coming up with innovative solutions for the AI-integrated robotic welding system. For instance, In July 2024, Novarc Technologies launched an intelligence robotic system, NovEye Autonomy Gen 2. This robotic welding system is integrated with AI computer vision technology, which provides adaptive welding features. Automation in robotic welding is expected to bring new trends to robotic welding systems, ultimately increasing the demand for AI-integrated robotic welding cells in the near future.

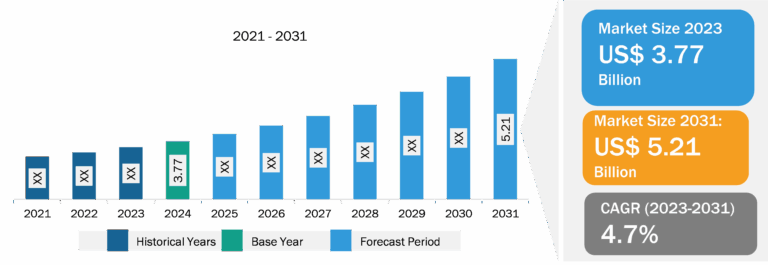

Robotic welding cell Market Analysis: offering Overview

Based on offering, the market is divided into solutions and services.

Based on the offering, the global robotic welding cell market is bifurcated into solutions and services. The solution segment accounted for a larger market share in 2023 and is expected to register a higher CAGR during the forecast period. Robotic welding cell solutions help manufacturers achieve their additional production capacity and mitigate labor shortage problems. Such advantages of robotic welding cells over manual welding processes are driving the demand for robotic welding cells.

Robotic welding cell Market: Competitive Landscape and Key Developments

Abb Ltd, Acieta LLC, Carl Cloos Schweisstechnik Gmbh, Kawasaki Heavy Industries, Ltd; Kuka AG; Phoenix Industrial Solutions; The Lincoln Electric Company; Wec Group Ltd.; Yaskawa America, Inc.; among others are among the key robotic welding cell market players profiled during this study. In addition, several other important robotic welding cell market players have been studied and analyzed during the study to get a holistic view of the robotic welding cell market and its ecosystem.

| Year | News | Country | ||

| Jun-2022 | ABB’s new OmniVance FlexArc Compact cell saves space adds flexibility to welding applications. ABB Ltd. launched its OmniVance FlexArc Compact – a new, smaller welding application cell with greater flexibility, ease-of-use and better integration – to help businesses address labor shortages in welding. The OmniVance FlexArc Compact is the smallest arc welding cell in its class. Its innovative 45-degree gantry robot mount design maximizes the robot’s working parameters by placing it in the center of a three-axis turntable, bringing it closer to the workpiece. | Global | ||