Ferroalloys Market

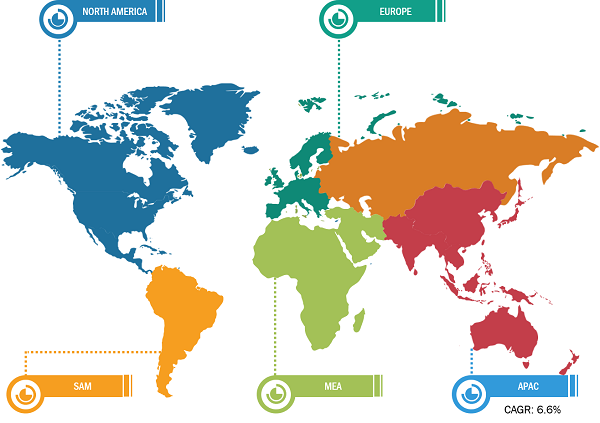

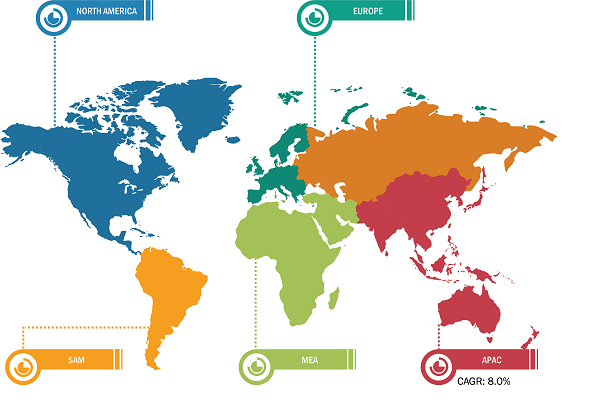

In 2022, Asia Pacific held the largest share in the ferroalloys market. The region’s extensive steel manufacturing industry drives substantial demand for ferroalloys, particularly ferrochrome, ferromanganese, and ferrosilicon, which are major raw materials in the steel-making industry. India has a strong steel industry fueled by infrastructure development, automotive manufacturing, and construction activities. Further, the emerging role of China and India as a global hub for electric vehicle manufacturing is expected to boost demand for ferrosilicon for the production of specialty steel used in automotive production.

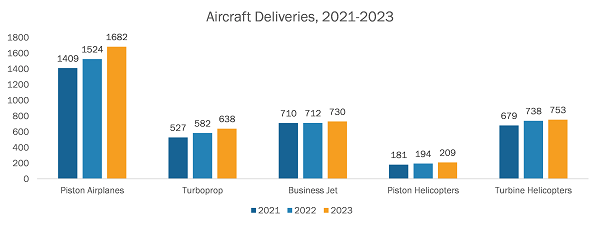

According to the International Organization of Motor Vehicle Manufacturers report, motor vehicle production in Asia Pacific was estimated to be 48.96 million units in 2022. As battery technology continues to improve, Asia Pacific is expected to become a key hub for electric vehicle production. China has emerged as one of the largest electric vehicle markets globally, supported by government policies promoting electric vehicles. As per the International Trade Administration, total investments in China’s infrastructure during the 14th Five-Year Plan period (2021–2025) are estimated to reach ~US$ 4.2 trillion. According to the National Investment Promotion & Facilitation Agency, India allocated an investment budget of US$ 1.4 trillion in infrastructure under the National Infrastructure Pipeline by 2025, of which 18% accounted for roads and highways, 17% accounted for urban infrastructure, and 12% for railways. Further, the growth in the global aerospace & defense industry is expected to create lucrative opportunities for the ferroalloys market expansion in the region during the forecast period.

Rising Demand for Ferroalloys in Automotive Industry Drives Ferroalloys Market

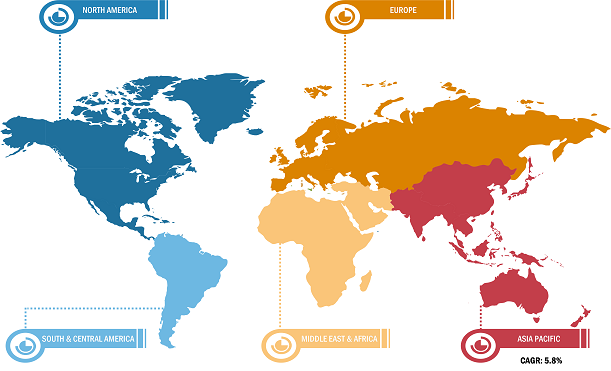

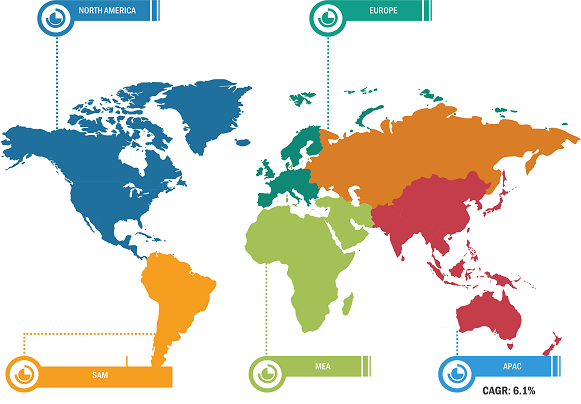

The automotive industry is experiencing robust growth owing to technological advancement and a surge in preference for SUVs, crossovers, and other light trucks. According to the report released by the European Automobile Manufacturers’ Association (ACEA) in January 2023, car production in North America increased by 10.3%, reaching 10.4 million units in 2022 compared to 2021. Similarly, passenger car production in South Korea grew by 7.6%, reaching 3.4 million units in 2022 compared to 2021. The report published by the ACEA stated that global passenger car production accounted for 68 million units in 2022, recording a rise of 7.9% compared to 2021.

As per the data of the Organisation Internationale des Constructeurs d’Automobiles (OICA), countries in North America, South America, and Central America recorded production of over 16.1 million commercial and passenger cars in 2021; the figure has grown by 10%, registering over 17.7 million commercial and passenger cars in 2022. Companies operating in the automotive sector are investing heavily in automobile manufacturing to increase production and sales. Thus, the rising demand for ferroalloys in the automotive industry contributes to the growing ferroalloys market size.

Ferroalloys Market: Segmental Overview

The global ferroalloys market is segmented on the basis of type and application. Based on type, the market is segmented into ferrochrome, ferromanganese, ferro silico manganese, special alloys, and others. The ferromanganese segment accounts for a significant ferroalloys market share. Ferromanganese is an alloy composed of manganese (~80–85%) and iron (approximately 15–20%), along with trace amounts of other elements such as carbon, silicon, and phosphorus. It is a crucial component in the steelmaking industry, where it serves as a deoxidizer and desulfurizer, enhancing the mechanical properties such as the strength, malleability, and corrosion resistance of steel. The production of ferromanganese typically involves the reduction of manganese oxide (MnO2) and iron oxide (Fe2O3) with carbon in a high-temperature furnace. The resulting alloy is then refined to remove impurities, yielding a product with specific manganese and iron content tailored to meet the requirements of various applications. Ferromanganese finds widespread use in the manufacturing of steel, particularly in the production of stainless and specialty steels used in construction, automotive, aerospace, and other industries. The addition of ferromanganese to steel improves its strength, toughness, and resistance to wear and corrosion, making it ideal for critical applications where reliability and durability are paramount. Also, ferromanganese has applications in the production of nonferrous alloys, such as aluminum alloys, where it aids in grain refinement and deoxidation.

Based on application, the global ferroalloys market is segmented into steel making, wire manufacturing, welding electrodes, superalloys, and others. The steel making and welding electrodes segments account for a significant market share. Ferroalloys are added to molten steel during the steelmaking process to achieve specific characteristics tailored to various applications. One of the most common ferroalloys used in steelmaking is ferrochrome; it contains chromium and is instrumental in imparting corrosion resistance, hardness, and high-temperature strength to stainless steel. Additionally, ferromanganese is employed to deoxidize and desulfurize steel, as well as to enhance its tensile strength and toughness. Ferroalloys also enable the production of specialty steels with unique properties suited for specific industries and applications. For instance, ferrosilicon is utilized to deoxidize alloy steel, improving its strength, magnetic properties, and resistance to corrosion and wear. Also, ferrotitanium and ferrovanadium are employed to introduce titanium and vanadium into steel, respectively. It enhances the strength, stability, and heat resistance of steel, making it ideal for applications in the aerospace, automotive, and construction sectors. Ferroalloys contribute to the efficiency and cost-effectiveness of steelmaking processes by facilitating the removal of impurities, refining the steel’s microstructure, and reducing energy consumption during melting and casting operations. Additionally, manganese is a key component of welding electrodes, serving as a deoxidizer and desulfurizer to improve the cleanliness and weldability of the molten metal. By scavenging impurities and forming stable oxides, manganese ensures better fusion between the electrode and base metal, resulting in high-quality welds with minimal defects. Silicon, another common ferroalloy in welding electrodes, enhances fluidity and arc stability during the welding process. It also contributes to the deoxidation of the weld pool, reducing the formation of undesirable inclusions and ensuring uniform distribution of alloying elements throughout the weld joint. Carbon, often present in the form of graphite or carbon black, helps regulate the electrical conductivity and arc characteristics of welding electrodes. By controlling the arc temperature and stability, carbon facilitates precise control over the welding process, ensuring consistent bead formation and penetration.

Ferroalloys Market: Competitive Landscape

Glencore Plc, Samancor Chrome, Jindal Stainless Ltd, Ferro Alloys Corporation Limited (FACOR), Erdos Group, Pertama Ferroalloys Sdn Bhd, Brahm Group, Tata Steel Ltd, Nikopol Ferroalloy Plant, and Nava Limited. are among the prominent players profiled in the ferroalloys market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The ferroalloys market report also includes company positioning and concentration to evaluate the performance of competitors/players in the market.