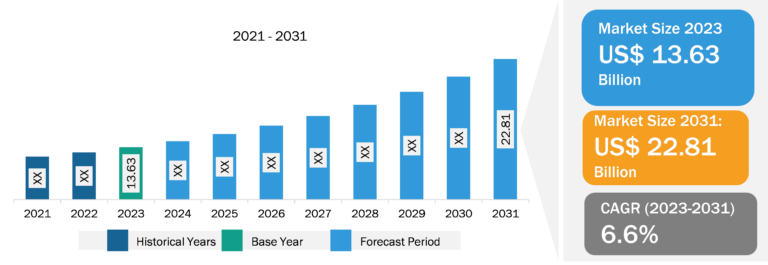

Machine Vision Lighting Market

Increasing Automation Across Industries to Fuel Machine Vision Lighting Market Growth During Forecast Period

Automation is revolutionizing the way businesses and industries operate across the world. Automation has enabled companies to become more cost-effective and efficient by excluding labor-intensive tasks and increasing production accuracy and speed. Automation also has the potential to improve product quality and decrease human error. It has allowed businesses to improve customer service, modernize their operations, and reduce customer wait times. Automation is also helping businesses become more flexible, allowing them to respond quickly to changes in the market. As businesses embrace automation, they quickly realize the benefits it can bring to their operations. Automation in industries is growing significantly. For instance, in June 2023, Rockwell Automation announced that 85% of automotive manufacturers plan to maintain or even increase their workforce due to the adoption of technology. In addition, 64% of businesses use software to automate processes, and 54% of leaders are increasing automation to address labor shortages. Also, according to SSE Automation data, industrial production has increased, and almost 90% of companies perceive benefits in automation. China and India represent 70% of industrial automation growth. Industrial automation is expected to create US$ 2.3 million jobs by 2025. As investments in automation increase and technology becomes more accessible, the market will witness massive growth.

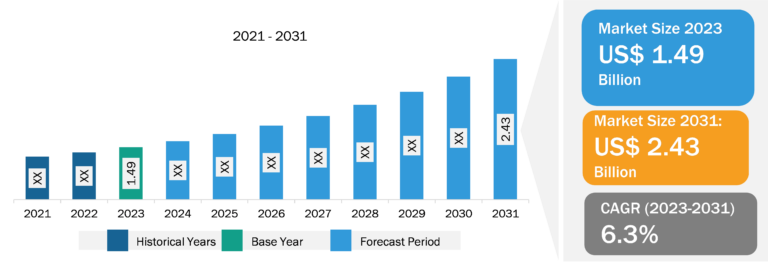

Systems in the machine vision lighting market with specialized lighting can identify imperfections and ensure adherence to strict quality requirements in producing automotive components such as engine parts or electronic control units. Also, automotive components must meet precise safety and performance standards. Systems in the machine vision lighting market with appropriate lighting play a critical role in inspecting components with high accuracy, ensuring that safety-critical features comply with regulations. For example, in the inspection of airbag components, systems in the machine vision lighting market equipped with precise lighting can identify even minor defects, contributing to the overall safety of the vehicle. Thus, the increasing demand for systems in the machine vision lighting market for the automotive industry is driven by the need for high-quality manufacturing, adherence to safety standards, efficient assembly processes, and the integration of vision technology in advanced automotive features.

Machine Vision Lighting Market: Industry Overview

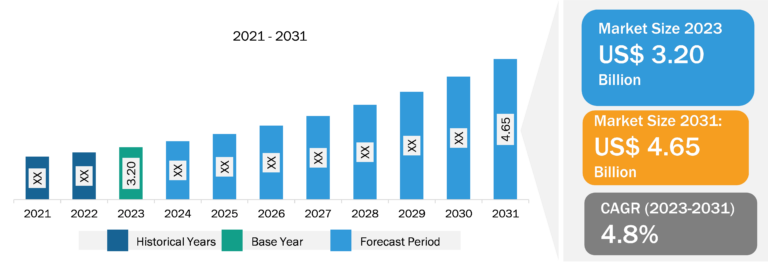

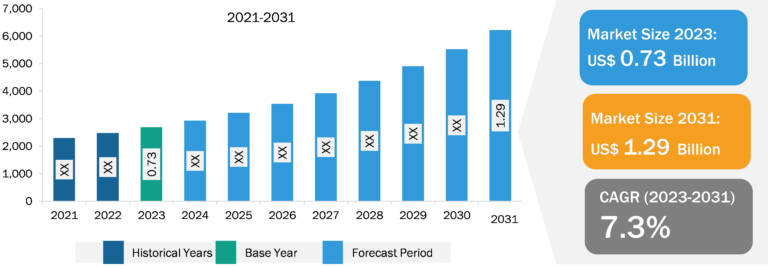

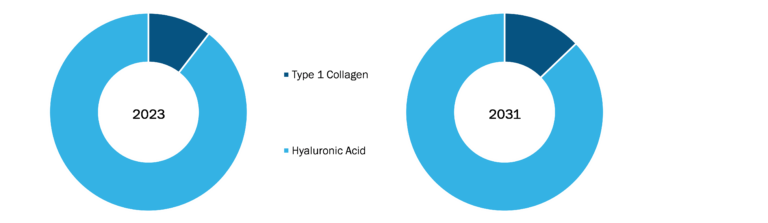

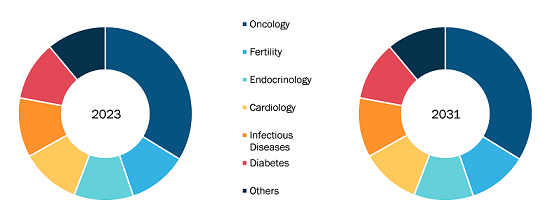

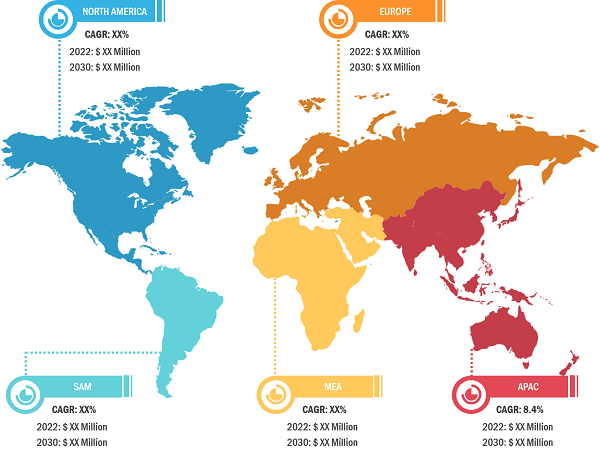

The machine vision lighting market is categorized based on lighting type, spectrum of light, and application. Based on lighting type, the machine vision lighting market is segmented into LEDs, fiber optic lights (halogen), fluorescent lighting, and xenon. By spectrum of light, the market is segmented into visible spectrum, UV spectrum, and IR spectrum. In terms of application, the machine vision lighting market is segmented into automotive, consumer electronics, food & beverage, pharmaceuticals, and logistics. Geographically, the machine vision lighting market is divided into North America, Europe, Asia Pacific, Middle East & Africa, and South & Central America.

The manufacturing industry trends in North America, specifically in the US, have been the most influential market trends globally for the past few years. This is majorly due to the region’s ability to remain the sole bright spot for economic recovery. Also, the manufacturing industry in this region gives significant importance to the country’s economy and workforce, which further drives the demand for supremely efficient manufacturing tools. Some major manufacturing industries in North America are aerospace, automotive, and construction.

Furthermore, Mexico’s manufacturing sector is experiencing tremendous growth. This includes industries such as automotive & aerospace, medical devices, and consumer electronics. Some of the largest consumer electronics and TV manufacturers, such as Sony, Phillips, Dell, and Panasonic, have set up their operations in Mexico. As per the US Bureau Of Labor Statistics data, 591,720 manufacturing businesses in the US represent many industries and services. This number represents facilities for food, transportation, manufacturing equipment, chemicals, petroleum and coal products, machinery, and electronics. This has resulted in the high adoption of automation, including systems in the machine vision lighting market. Further, even Canada is experiencing a declining dollar and availability of cheaper power, thereby positively influencing the growth of the manufacturing sector.

North America is also considered one of the most competitive landscapes, attracting numerous manufacturing and technology-based companies to venture into this region. However, the uncompetitive legacy commitments, lax corporate governance, and high structural and acquiescence costs are projected to hinder manufacturing competitiveness in a few industries. Similarly, restrictive immigration policies and uncompetitive labor and tax policies can also put North American manufacturers at a notable disadvantage against their competitors worldwide.

Nonetheless, the rising focus of the manufacturing industries on enhancing their quality standards and manufacturing policies has led to an increase in the demand for lighting systems, image boards, and software for vision systems, generating ample opportunities for the machine vision lighting market to grow moderately in North America during the forecast period.

Machine Vision Lighting Market: Competitive Landscape and Key Developments

Cognex Corporation, Advanced Illumination Inc., Effilux, Moritex Corporation, National Instruments Corporation, Omron Microscans Systems Inc., Prophotonix Limited, Spectrum Illumination, and TPL Vision are among the leading market players profiled in the machine vision lighting market report. Several other essential market players were analyzed for a holistic view of the market and its ecosystem. The report provides detailed market insights, which help the key players strategize their market growth. A few developments are mentioned below:

- In September 2023, The Wenglor Sensoric Group announced the official inauguration of the WenglorCenter at its new location in Unterschleißheim. Following an extensive construction period of nearly three years, the employees of WenglorMEL successfully transitioned from their previous site in Eching to the new facility in Unterschleißheim in June. The new building incorporates cutting-edge technologies and intelligent design concepts to create an optimal working and production environment that is both comfortable and resource-efficient. This development is particularly significant as Wenglor continues to expand its global workforce, which currently exceeds 1,100 employees.

- In October 2021, CCS launched OLB-LT series bendable OLED lighting for machine vision inspection. The launched product is the second product under CCS-LT. The OLB-LT series uses a multi-layer design of organic light-emitting diodes (OLED) and spring steel so that the bending radius can be designed from 100 mm with either an inner or outer light emission surface while reducing the impact to the 0.1 mm flexible glass.