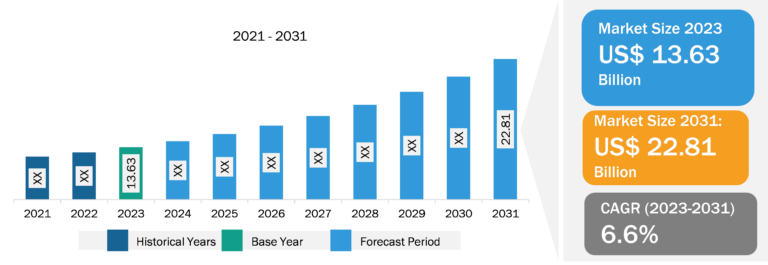

Isostatic Pressing Market

Increasing Technological Advancements to Fuel Isostatic Pressing Market Growth During Forecast Period

Technological advancements contribute to the development of new and advanced materials. Isostatic pressing can capitalize on these innovations to shape and consolidate materials with enhanced properties. Emerging materials, such as metal matrix composites or advanced ceramics, can be efficiently processed using isostatic pressing to create components with improved strength, wear resistance, and thermal stability. The integration of Industry 4.0 technologies, such as IoT sensors and real-time monitoring, into isostatic pressing equipment enhances process control, efficiency, and predictive maintenance. Smart isostatic pressing machines equipped with sensors can monitor variables such as pressure and temperature, allowing for real-time adjustments and minimizing downtime. Also, the concept of digital twins, creating virtual replicas of isostatic pressing processes, enables simulation and optimization. This contributes to improved efficiency and product quality. Manufacturers can analyze and optimize parameters without physical trials by creating a digital twin of the isostatic pressing process, reducing development time and costs. Advances in precision engineering and automation contribute to increased accuracy and repeatability in isostatic pressing processes, ensuring consistent quality in shaped components. Automated loading and unloading systems combined with precision control mechanisms enhance the accuracy of shaping materials during the isostatic pressing process. Technological advancements in tooling and die design enhance the capabilities of isostatic pressing, allowing for the production of components with complex shapes and intricate details. Advanced die designs with improved cooling mechanisms can optimize the shaping process and enable the production of high-quality components. Hence, technological advancements are expected to be an opportunity for the isostatic pressing market.

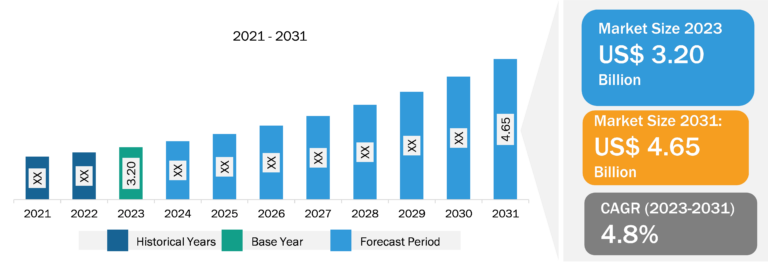

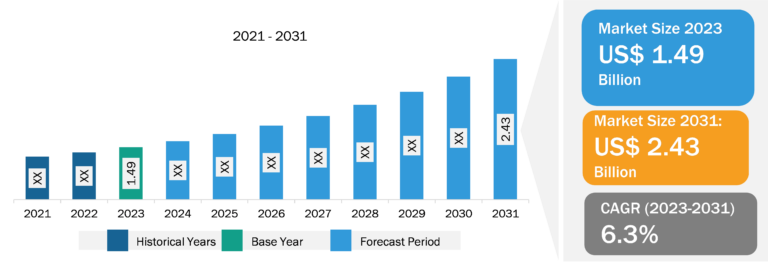

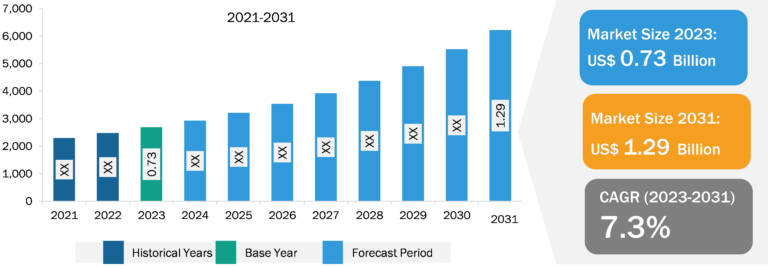

Isostatic Pressing Market: Industry Overview

The isostatic pressing market is segmented based on offering, type, application, and geography. Based on offering, the isostatic pressing market is segmented into systems and services. Based on type, the isostatic pressing market is segmented into hot isostatic pressing (HIP), cold isostatic pressing (CIP), and warm isostatic pressing (WIP). Based on application, the isostatic pressing market is segmented into automotive, aerospace and defense, precision machine manufacturing, medical, energy and power, and others. Based on geography, the isostatic pressing market is segmented into North America, Europe, Asia Pacific, the Middle East & Africa, and South America.

The global isostatic pressing market is segmented into five major regions: North America, Europe, Asia Pacific, the Middle East & Africa, and South America. In 2022, Asia Pacific led the global isostatic pressing market with a substantial revenue share, followed by North America and Europe. The isostatic pressing market in South America is segmented into Brazil, Argentina, and the Rest of SAM. South America has been experiencing significant growth in its industrial sector. Industries such as energy and power are dominant in the region. According to the International Association of Oil & Gas Producers, the total energy supply in the region was 26,912,417 TJ in 2021. Also, the wind energy industry is growing significantly in SAM. According to the Global Wind Energy Council, 3.7 GW of onshore wind was installed in the region in 2019, with 51% by Brazil, 25% by Mexico, and 13% by Argentina. In total, there is close to 26 GW of onshore wind installed in Latin America, with 57% in Brazil and 19% in Mexico. Isostatic pressing is involved in shaping components for energy storage systems, including batteries and capacitors. Components manufactured through isostatic pressing can offer improved structural integrity and reliability, contributing to the efficiency and performance of energy storage systems in power grids. Therefore, the demand for isostatic pressing is increasing in South America, with the growing energy & power sector.

Isostatic Pressing Market: Competitive Landscape and Key Developments

American Isostatic Presses Inc., Bodycote Plc, EPSI Inc., Fluitron Inc., Hiperbaric USA Corp, Kennametal Inc., Kobe Steel Ltd, Nikkiso Co Ltd, Pressure Technology Inc., and Shanxi Golden Kaiyuan Co Ltd are among the leading players profiled in the isostatic pressing market report. Several other essential isostatic pressing market players were analyzed for a holistic view of the market and its ecosystem. The report provides detailed market insights, which help the key players strategize their market growth. A few developments are mentioned below:

- In May 2023, Quintus Technologies, a subsidiary of Kobe Steel Ltd, introduced a new product called the Purus Toolbox for Hot Isostatic Pressing (HIP). This innovative toolbox is designed to enhance the capabilities and efficiency of the hot isostatic pressing process. The Purus Toolbox for HIP is a comprehensive solution that combines software, hardware, and process expertise to optimize the HIP process. It offers advanced features such as real-time monitoring and control, data analysis, and process simulation. These capabilities enable manufacturers to achieve higher productivity, reduce costs, and improve the quality of the final products.

- In March 2023, US-based American Isostatic Presses Inc. integrated a rapid cooling system into its research and development of Hot Isostatic Press (HIP) for Additive Manufacturing. This implementation of rapid cooling can replace the requirement for supplementary heat treatments, such as quenching and solution heat treatment. The introduction of this new system is anticipated to facilitate the advancement of additive manufacturing applications.

- In July 2022, Bodycote started the expansion of its Hot Isostatic Pressing (HIP) capability in Greenville, South Carolina, US. As the world’s largest contributor to thermal processing services, Bodycote is strategically investing in its HIP capabilities to meet the increasing demand for advanced metallurgical solutions.

- In February 2021, Bodycote announced the inauguration of a new state-of-the-art facility in Syracuse, New York, USA. This expansion signifies Bodycote’s commitment to expanding its operations and enhancing its service offerings to better serve its customers in the region.