Hot Melt Adhesives Market

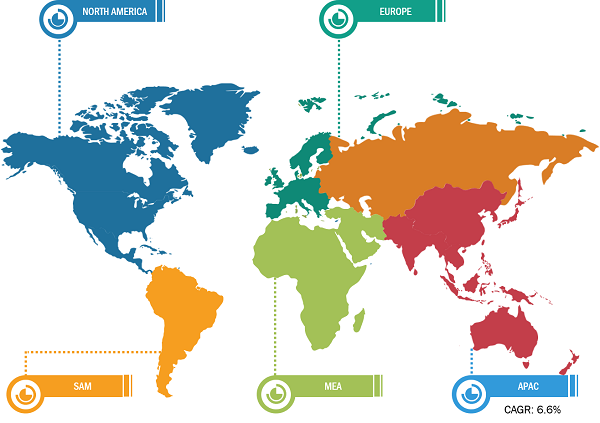

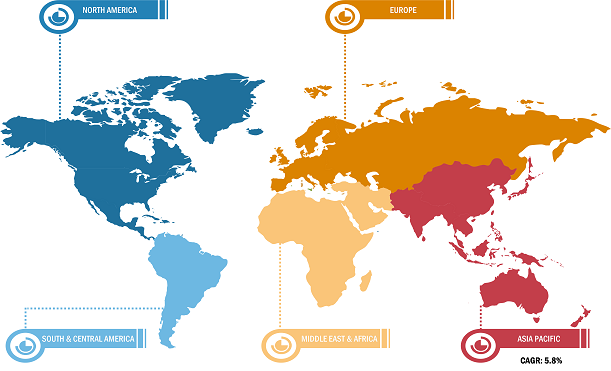

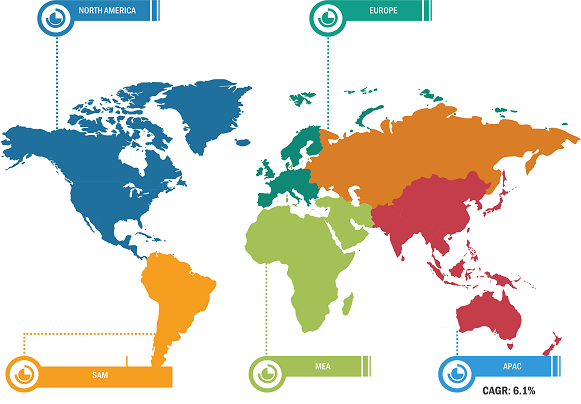

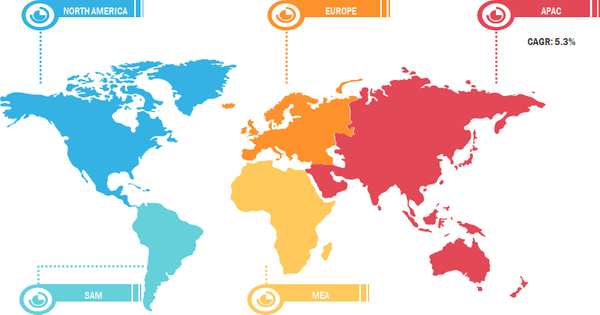

In 2022, Asia Pacific held the largest global hot melt adhesives market share. Rising adoption of e-commerce and increasing purchasing power of consumers bolster the market growth in Asia Pacific. Shift in preference toward sustainable materials is expected to offer opportunities for adhesive manufacturers, especially in Asia Pacific, which is projected to be the largest consumer of hot melt adhesives during the forecast period. Rise in need for medical and hygiene products such as PPE suits, medical supplies, personal hygiene products, masks, and paper products propels the demand for hot melt adhesives from the manufacturing industries of these products. In addition, increasing use of packaging products in the fast moving consumer goods (FMCG) and e-commerce sectors would bolster the hot melt adhesives market growth in countries such as India and China.

Adoption of Bio-Based Hot-Melt Adhesives Drives Hot Melt Adhesives

Consumers demand bio-based and compostable hot melt adhesives that are environmentally friendly. Henkel has developed bio-based hot melt adhesives technology, particularly suited for sustainability and circular economy uses. This development is mainly focused on reducing dependency on petroleum-based raw materials and diminishing the carbon footprint of different manufacturing operations. As one of the leading developers of these biobased hot melt adhesives chemistries, Henkel stated that it is looking to improve the way companies enhance their sustainable packaging initiatives. Ethylene vinyl acetate is used in biobased hot melt adhesives due to their eco-friendly and reliable nature. Using biobased and compostable hot melt adhesives, landfills can be saved to a larger extent.

Hot Melt Adhesives Market: Segmental Overview

Based on type, the hot melt adhesives market is segmented into ethylene vinyl acetate, polyolefins, polyamides, polyurethanes, styrene block copolymers, and others. The ethylene vinyl acetate segment held the largest hot melt adhesives market share in 2022. Ethylene vinyl acetate (EVA) is used in many hot melt adhesives due to its rubber-like flexibility. EVA-based adhesives are flexible enough to withstand cracking, especially when exposed to UV light. These adhesives are durable, even in harsh temperatures. EVA-based adhesives do not require the use of water or solvents to achieve their adhesive qualities, which allows them to set quickly and operate effectively throughout a wide temperature range. The adhesives are used in a wide range of industries, including paper, woodworking, assembly, and automotive.

The hot melt adhesives market, based on application, is segmented into packaging, construction, automotive, furniture, footwear, electronics, and others. The packaging segment held the largest share of the

market in 2022. The packaging applications of hot melt adhesives mainly include carton or box sealing, bottle labeling, paper bag manufacturing, and bag assembly. Hot melt sticks are mainly used for wooden box closing. These adhesives are preferred over water-based adhesives due to shorter set time, better adhesion, and water-resistance.

Impact of COVID-19 Pandemic on Hot Melt Adhesives Market

Before the COVID-19 pandemic, the hot melt adhesives market was driven by their increasing use in packaging, construction, and other applications. However, due to the pandemic, governments of various countries across the world imposed country-wide lockdowns that directly impacted the growth of the industrial sector. The shutdown of production facilities negatively impacted the hot melt adhesives market growth in 2020. The adverse impact of the pandemic on construction, automotive, packaging, and many other industries has reduced the demand for hot melt adhesives.

Numerous industries regained momentum with the ease of lockdown measures, which increased the demand for hot melt adhesives. Further, various economies began reviving with the resumption of operations in different sectors in 2021. The hot melt adhesives market is growing with increasing demand from various end-use industries such as automotive and packaging.

Hot Melt Adhesives Market: Competitive Landscape and Key Developments

H.B. Fuller Company, Henkel AG & Company KGaA, Arkema, 3M, Sika AG, Jowat SE, Hexcel Corporation, The Dow Chemical Company, Beardow Adams, and Gorilla Glue Company are a few players operating in the global hot melt adhesives market. Global market players focus on providing high-quality products to fulfill customer demand. Also, they focus on adopting various strategies such as new product launches, capacity expansion, partnerships, and collaboration to stay competitive in the market.

Key Developments

- In December 2019, Arkema announced the acquisition of LIP Bygningsartikler AS (LIP) by Bostik. LIP provides tile adhesives, waterproofing systems, and floor preparation solutions. This acquisition has enabled Bostik to offer an extended range of high-value-added products to its customers while boosting its presence in Nordic countries.

- In 2021, Sika AG acquired Hamatite, a Japan-based company that provides adhesives and sealants to various industries such as automotive and construction. The company also offers various technologies, such as polyurethanes, hot melts, and modified silicones. This acquisition will help Sika AG to strengthen its position in Japan and increase market access.

- In 2020, H.B. Fuller Company launched new products—Advantra 9280 EU and Advantra BOLD 9480, readily available adhesive grades with hot melt advanced technology for extreme cold storage of vaccines and medication packaging.

- In 2021, Henkel AG & Co. KGaA launched the industry’s first bio-based polyurethane reactive (PUR) hot melt adhesive. The product LOCTITE HHD 3544F is designed for consumer electronics assembly.

- In 2021, Henkel AG & Co. KGaA launched sustainable packaging hot melt adhesives in a partnership with Dow. This new Technomelt Supra ECO range of products has been developed to enable customers to reach their sustainability goals.

- In 2020, Bostik launched Thermogrip 2356, a new product line for label adhesive, which is specially designed to enhance production line efficiencies and enable sustainable packaging for quick-service restaurant applications. The product is formulated with hot melt pressure-sensitive adhesive technology.