Digital Twin Market

Surging Emphasis on Predictive Maintenance to Fuel Digital Twin Market Growth During Forecast Period

Predictive maintenance is perceived as the most advanced means to manage maintenance within manufacturing plants. This maintenance approach is enabled by the implementation of technologies such as AI, ML, the Internet of Things (IoT), and Big Data to monitor equipment and check for part failure. Predictive maintenance helps save maintenance costs by selectively detecting the parts that need attention. It also guides organizations to make small repairs in a timely manner, which aids the extended lifecycle of equipment and helps reduce downtime. A targeted maintenance approach enabled by predictive maintenance reduces unnecessary inspections and repairs and facilitates early intervention to prevent serious and complex problems down the line. Due to such benefits, predictive maintenance has increasingly been used in economically critical industries, such as manufacturing and automotive, in recent years. According to the Department of Energy, maintenance teams from different organizations expect an upsurge of 25% in production outcomes after the implementation of a predictive maintenance strategy and software.

Industries increasingly rely on predictive maintenance, as minimizing downtime is a critical aspect of any business. Digital twins operate by continuously gathering data on asset conditions, enabling predictive maintenance solutions to identify patterns and potential failures before they occur. With digital twin technology, maintenance teams can also remotely monitor assets’ performance and diagnose issues without physically inspecting them. Thus, a growing focus on predictive maintenance bolsters the digital twin market growth.

Digital Twin Market: Industry Overview

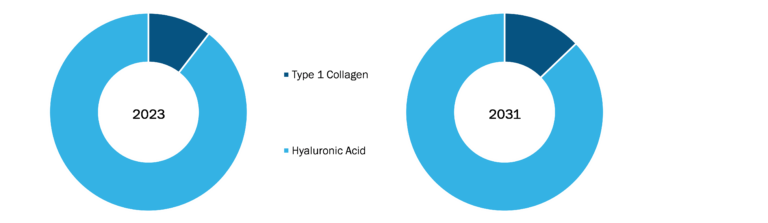

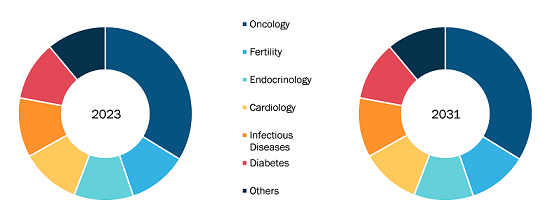

The digital twin market is segmented based on type, enterprise size, end user, and geography. Based on type, the market is segmented into asset twin, system twin, process twin, and parts/component twin. By enterprise size, the market is bifurcated into large enterprises and SMEs. In terms of end user, the digital twin market is segmented into manufacturing sector, automotive sector, aerospace & defense sector, healthcare sector, retail sector, and others. Geographically, the digital twin market is segmented into North America, Asia Pacific, Europe, the Middle East & Africa, and South & Central America.

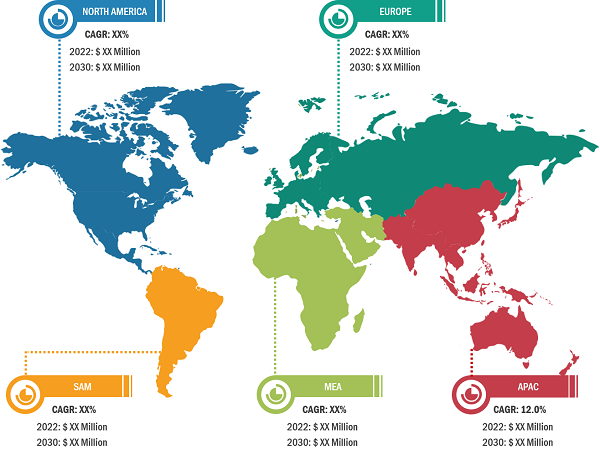

In terms of revenue, North America dominated the digital twin market share, followed by Europe and APAC. The digital twin market in North America is segmented into the US, Canada, and Mexico. The US is expected to hold the largest digital twin market share and record the highest CAGR during 2023–2031. The high digitization rate in various industries, a rise in the adoption of digital tools, and high technological spending by government agencies in the US fuel the digital twin market growth in the US. The US government is also taking various measures to boost the adoption of digital twin technology in the country. In May 2024, the Biden-Harris Administration issued a Notice of Funding Opportunity (NOFO) seeking proposals from eligible applicants for activities to establish and operate a CHIPS Manufacturing USA institute focused on digital twins for the semiconductor industry. Under this, CHIPS for America announced a US$ 285 million funding opportunity for a digital twin and semiconductor CHIPS Manufacturing USA Institute. Moreover, the US has a large number of market players who have been increasingly focusing on developing innovative solutions. A few of the key players operating in the US are IBM Corporation, Oracle, Microsoft, ANSYS Inc., and PTC.

Digital Twin Market: Competitive Landscape and Key Developments

General Electric Co, Microsoft Corp, Siemens AG, Dassault Systemes SE, PTC Inc, Robert Bosch GmbH, International Business Machines Corp, Oracle Corp, Ansys Inc, and Autodesk Inc are among the leading players profiled in the digital twin market report. Several other essential market players were analyzed for a holistic view of the market and its ecosystem. The digital twin market report provides detailed market insights, which help the key players strategize their market growth. As per the company press releases, below are a few recent key developments:

- In April 2024, Siemens and Microsoft announced their commitment to converge the digital twin definition language (DTDL) with the Thing Description standard from international standards organization W3C. By unifying both languages, customers are offered consistent modeling experiences, mitigating fragmentation in an evolving IoT landscape. With customers typically deploying a mix of vendors in their infrastructure, leading to lock-in and high integration efforts, this convergence will allow for simpler system integration and interoperability.

(Source: Siemens, Press Release)

- In June 2023, Helixx, a new UK-based global technology company, selected the Siemens Xcelerator portfolio of industry software and services to assist in the design, development, validation, delivery, and management of its innovative electric vehicle manufacturing system.

(Source: Helixx, Press Release)