Form-In Place Gasket Market

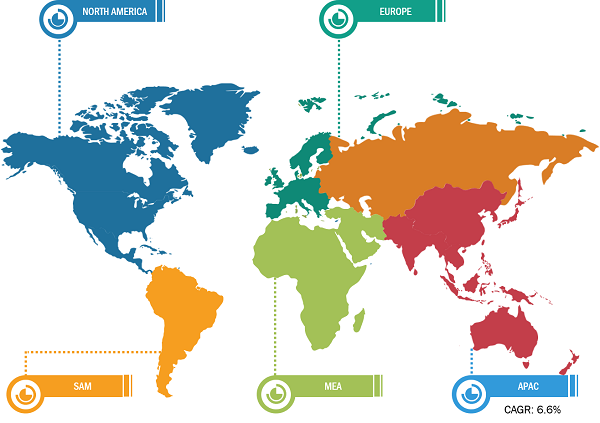

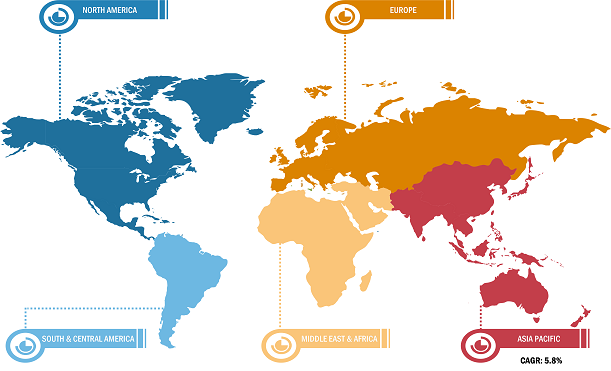

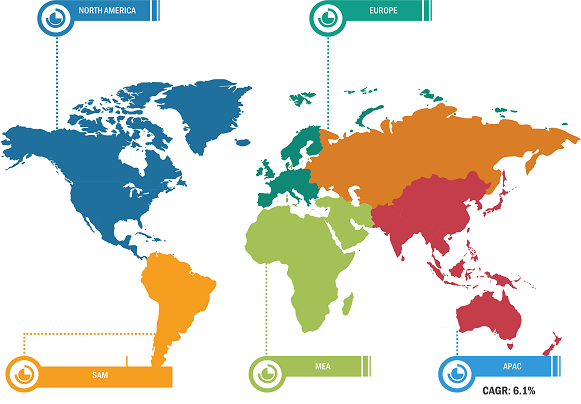

In 2022, Asia Pacific dominated the global form-in place gasket market. The demand for form-in-place gaskets in Asia Pacific is directly proportional to industrialization and vehicular production in the region. The increasing number of on-fleet vehicles in countries such as China, India, and South Korea propels the demand for printed circuit boards (PCBs) and semiconductors, further bolstering the need for form-in-place gaskets. With China’s evolution into a high-skilled manufacturing hub, developing countries such as India, Taiwan, South Korea, and Vietnam are attracting several businesses that plan to relocate their low to medium-skilled manufacturing facilities to neighboring countries, which results in reduced labor costs. As per the study by the Semiconductor Industry Association, ~75% of global semiconductor capacity is based in East Asia. Semiconductor companies will benefit from a cost advantage of 25% to 50% with the start of manufacturing activities in the region.

High Demand for Form-In-Place Gaskets from Automotive Industry Drives Form-In Place Gasket Market Growth

Form-in-place gaskets are commonly used in engine applications to create seals between engine components. They are employed in areas such as cylinder heads, valve covers, and oil pans to ensure the proper functioning of the engine and prevent leaks. In addition, form-in-place gaskets are applied in the sealing of electronic control units and protecting sensitive electronic components from environmental factors such as moisture and contaminants. Form-in-place gaskets are often used in electric and hybrid vehicles to seal battery enclosures, thereby maintaining the safety and integrity of the battery system. The ability of form-in-place gaskets to be customized according to specific shapes and sizes makes it suitable for various custom sealing applications in the automotive industry. The advancements in automotive manufacturing capabilities and rising demand for electric vehicles drive the global automotive industry. Automotive is one of the leading industries in Europe as it contributes significantly to the GDPs of European countries, including Germany, Italy, the UK, and others. Additionally, form-in-place gaskets are used to seal flanges in pipelines and equipment within the oil and gas infrastructure. The gaskets provide a secure and leak-resistant seal between connected flanges, preventing the escape of fluids and gases. In oil and gas wellheads, where pressure and temperature conditions can be extreme, form-in-place gaskets are used to seal critical connections. During the construction and maintenance of pipelines, form-in-place gaskets are used to seal the connections between pipeline segments. These gaskets are applied in the sealing of tanks and vessels used for storage and transportation of oil and gas. According to the Pipeline and Hazardous Materials Safety Administration, in North America, ∼2.6 million miles of pipelines deliver hundreds of billions of tons of liquid petroleum products and trillions of cubic feet of natural gas yearly. Per the Canada Energy Regulator, most of the crude oil produced in Canada is shipped using pipelines from western provinces to refineries in the US, Ontario, and Quebec. The Energy Research Office (EPE), a division of the Brazilian Ministry of Energy, published the Transport Gas Pipeline Plan 2022–2026 (PIG) to serve as a proposal for investments in the construction of gas pipelines at a national level. Under this plan, the company planned to invest US$ 4 billion in the construction of five gas pipelines focusing on gas flow from the Sergipe and Alagoas basins, in addition to gas from the pre-salt field. Thus, the high demand for form-in-place gaskets from automotive Industry drives the form-in place gasket market.

Form-In Place Gasket Market: Segmental Overview

Based on application, the form-in place gasket market is segmented into marine, automotive, electrical and electronics, aerospace, lighting, and others. In the field of electrical and electronics, form-in-place gaskets are commonly employed in smartphones, tablets, and wearable devices. The ability of form-in-place gaskets to conform precisely to intricate designs and accommodate miniaturized components contributes to the sleek and compact form factors of these devices while maintaining resistance to external elements. This is particularly relevant in the evolving landscape of portable electronics, where durability and water resistance have become significant selling points. Moreover, in recent years, the automotive industry has witnessed the utilization of form-in-place gaskets, with manufacturers increasingly recognizing their versatility and performance benefits. The formulation of form-in-place gasket materials with enhanced resistance to extreme temperatures, ensuring reliable sealing in high-temperature engine compartments and harsh weather conditions, encounters increased utilization.

Impact of COVID-19 Pandemic on Form-In Place Gasket Market

Before the COVID-19 pandemic, many countries reported economic growth. Form-in place gasket manufacturers invested in research to develop advanced technology and improve production efficiency. Major market players also focused on geographic expansion through merger and acquisition strategies to cater to a broad customer base. The chemicals & materials industry announced a slowdown of manufacturing operations and shutdown, as well as projected a slump in form-in place gasket sales after the emergence of the COVID-19 outbreak. Thus, major companies involved in form-in place gasket production faced the hardest hit during the initial phase of the pandemic due to sudden government restrictions on the manufacturing of nonessential commodities. In 2021, several chemicals & materials companies began recovering from the losses incurred in 2020 with the revival of production operations. Manufacturers were permitted to operate at full capacities, which helped them cope with the demand-supply gap. With economies reviving their operations, the demand for form-in place gaskets started rising globally as the industry resumed its operations at full capacity.

Form-In Place Gasket Market: Competitive Landscape 3M Co, Henkel AG & Co KGaA, Parker Hannifin Corp, Modus Advanced Inc, Dow Inc, Compagnie de Saint Gobain SA, Permabond LLC, Bostik SA, HB Fuller Co, and ITW Performance Polymers are a few players operating in the global form-in place gasket market. Players operating in the global form-in place gasket market focus on providing high-quality products to fulfill customer demand.