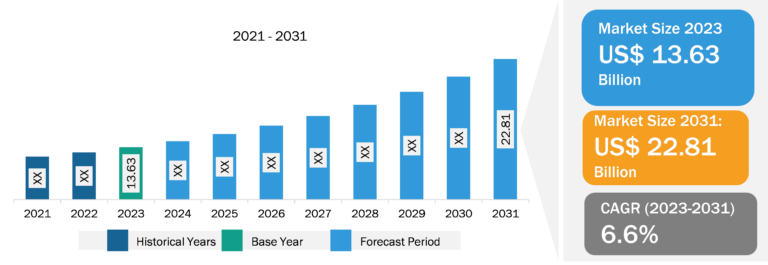

Carbon Fiber-Based SMC BMC Market

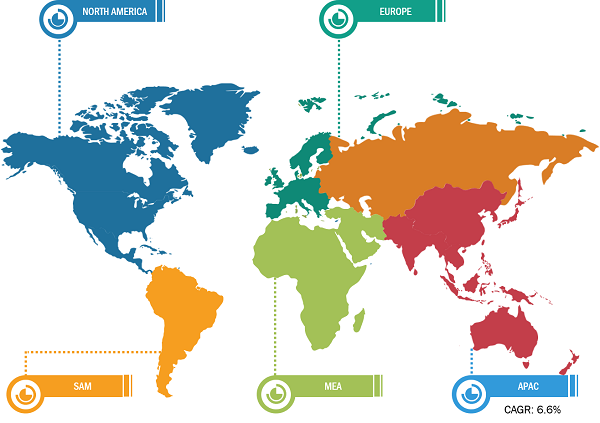

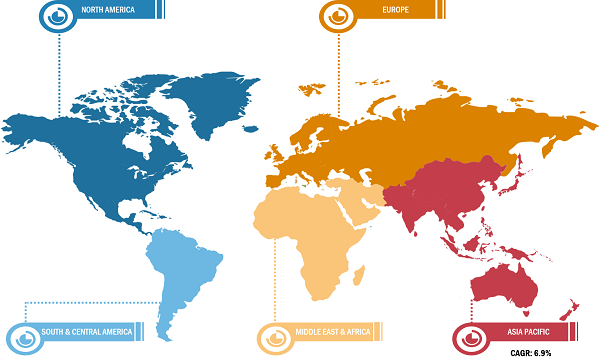

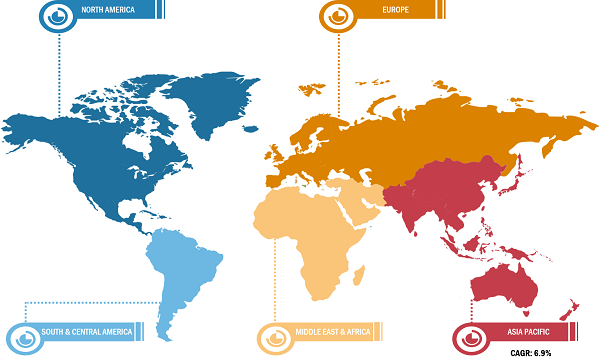

In 2022, Asia Pacific dominated the global carbon fiber-based SMC BMC market. The market growth in Asia Pacific is driven by the strong presence of the automotive, building & construction, electronics, wind energy, and other industries. Asia Pacific is a hub for automotive manufacturing with a large presence of international and domestic players operating in the region. According to a report published by the China Passenger Car Association, Tesla Inc delivered 83,135 made-in-China electric vehicles in 2022, indicating growth in sales of electric vehicles compared to 2021. The International Organization of Motor Vehicle Manufacturers report states that various countries in Asia Pacific produced ~46.73 million units of motor vehicles in 2021. In the production of cars, trucks, buses, and agricultural vehicles, SMC and BMC products offer advantages such as parts consolidation, corrosion resistance, low weight, and others. Further, China, Japan, and South Korea are among the major nations in the shipbuilding sector. According to The States Council of The People’s Republic of China, the shipbuilding output of China was 9.61 million deadweight tons (dwt) in 2022, accounting for 46.2% of the world’s total, up 2.8% year-on-year. SMC and BMC products find application in shipbuilding. Marine fiber-reinforced plastic has great potential for reducing structural weight due to its lightweight and high strength. Thus, the growing shipbuilding activities in the region fuel the carbon fiber-based SMC and BMC market growth in Asia Pacific.

Growing Global Automotive Industry

According to a report published by the European Automobile Manufacturers’ Association (ACEA), global motor vehicle production rose by 1.3% from 2020 to 2021, and 79.1 million motor vehicles, including 61.6 million passenger cars, were produced across the world in 2021. According to a report by the Bureau of Transportation Statistics, China is one of the dominant markets for producing passenger cars and commercial vehicles. According to a report by Germany Trade & Invest, Germany is a major automotive market in Europe, and the market in this country registered a foreign market revenue of US$ 289 billion in 2021 (a 10% rise from 2020) from passenger car and light commercial vehicle original equipment manufacturers.

Automotive is one of the leading industries in Europe as it contributes significantly to the GDPs of European countries, including Germany, Italy, the UK, and others. According to the report by the European Commission, turnover generated by the automotive industry in Europe represents 7% of the region’s total GDP. As per a report by the International Energy Agency in 2022, 2.3 million electric vehicles were sold in Europe in 2021 (a rise from 1.4 million in 2020). According to the US Commercial Service report, companies such as Bayerische Motoren Werke AG and Automobili Lamborghini SpA produce cars constituting composites, making ~6–8% of vehicle weight. Carbon fiber-based SMC are used as alternative to composites or metals in automotive industry. The growing emphasis on development of high efficiency and electric vehicles has fueled the demand for SMC and BMC in the past few years. Lightweight carbon fiber-based SMC is an efficient alternative to metals and conventional SMCs. Therefore, growing emphasis on lightweight vehicles in the automotive industry is expected to drive the demand for carbon fiber-based SMC and BMC.

Carbon Fiber-Based SMC BMC Market: Segmental Overview

Based on resin type, the carbon fiber-based SMC BMC market is segmented into polyester, vinyl ester, epoxy, and others. The polyester segment held the largest market share in 2022 and is expected to record the highest CAGR from 2022 to 2030. Polyester is a synthetic polymer usually derived from petroleum. It is a versatile material known for its strength, durability, and resistance to several environmental factors. These unsaturated resins are combined with other chemicals called hardeners or catalysts, which change the molecular structure of the resulting compound along with the generation of heat. Carbon fiber-based SMC and BMC are used in various end-use industries, including automotive, construction, and electronics. Compared to other resins, the processing of polyester is easier, cost-effective, and needs no post-curing. Polyester manufacturers work on new and improved formulations with better mechanical properties.

Based on end-use industry, the carbon fiber-based SMC BMC market is segmented into automotive, aerospace, electrical and electronics, building and construction, and others. The automotive segment held the largest carbon fiber-based SMC BMC market share in 2022. The utilization of SMC and BMC in the automotive industry can be attributed to its properties such as lightweight, durability, corrosion resistance, and design flexibility. The automotive industry has emphasized the production of lightweight components, thereby replacing metals and alloy materials. Thus, SMC and BMC manufacturing processes have gained popularity in the past few years. SMC and BMC can be engineered to reduce noise and vibration in vehicles and lower emissions.

Impact of COVID-19 Pandemic on Carbon Fiber-based SMC BMC Market

Before the COVID-19 pandemic, many countries reported economic growth, whereas carbon fiber-based SMC BMC manufacturers invested in research to develop advanced technology and improve production efficiency. The chemicals & materials industry announced a slowdown of manufacturing operations and shutdown, as well as projected a slump in carbon fiber-based SMC BMC sales. Thus, major companies involved in carbon fiber-based SMC BMC production faced the hardest hit during the initial phase of the pandemic due to sudden government restrictions on the manufacturing of nonessential commodities. In 2021, several developed economies began recovering from the losses incurred in 2020 as governments of various countries announced relaxation in social restrictions. Manufacturers were permitted to operate at full capacities, which helped them cope with the demand-supply gap. With economies reviving their operations, the demand for carbon fiber-based SMC BMC started rising globally as the automotive, aerospace, and electrical & electronics industries resumed their operations at full capacity.

Carbon Fiber-Based SMC BMC Market: Competitive Landscape and Key Developments

Teijin Carbon Europe GmBH, Mitsubishi Chemical Corp, ASTAR SA, Menzolit, Polynt SpA, IDI Composite International, LyondellBasell Industries Holdings BV, Lattice Composites LLC, Toray Advanced Composites, and YS ACC are a few players operating in the global carbon fiber-based SMC BMC market. Players operating in the global carbon fiber-based SMC BMC market focus on providing high-quality products to fulfill customer demand.

Key Developments

- In 2023, Engenuity developed a new approach to SMC, Failure in Random Material Architectures (FiRMA). This uses a predictive technique that accurately reflects material properties and determines the performance range an SMC part or structure will exhibit.

- In 2021, AOC, Zoltek, and Astar developed novel CF-SMC for high-performance automotive parts on an industrial scale. AOC AG (Schaffhausen, Switzerland), with Astar (Biscay, Spain), has developed a new sheet molding compound based on Daron polyurethane hybrid technology under the UK government-funded research project, TUCANA.