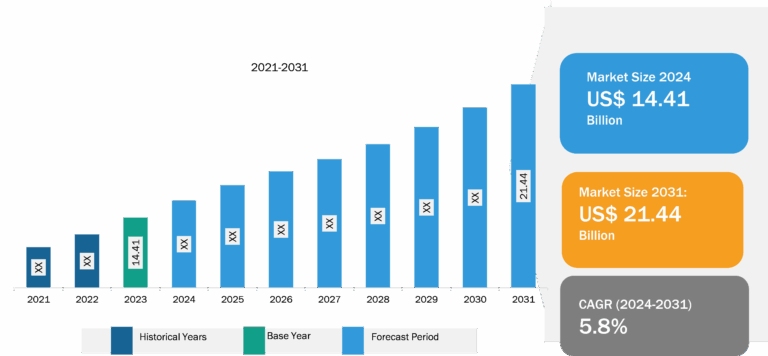

Masterbatch Market

A masterbatch is a concentrated mixture produced by the distribution of colors and additives into a polymer carrier with the support of heat treatment in high shear mixing extruder. The mixture is then cooled, cut, and formed into granules via pelletizer. The masterbatch is commonly used in polymer processing to incorporate color pigments or additives and antimicrobials into the polymer resin. Polymer resin such as polyethylene, polypropylene, PET, and polystyrene uses masterbatch for polymer products. Masterbatch is effective in offering physical and mechanical features of the product. Building and construction, automotive, packaging, agriculture, and electrical and electronics are among the end-use industries in the masterbatch market.

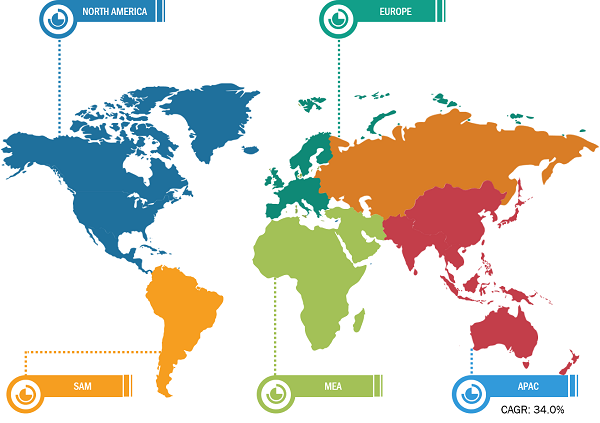

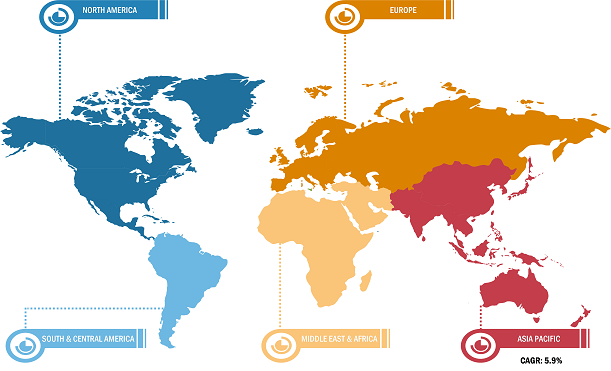

In 2023, Asia Pacific dominated the masterbatch market. As per the International Trade Administration, total investments in China’s infrastructure during the 14th Five-Year Plan period (2021–2025) are estimated to reach ~US$ 4 trillion. According to the National Investment Promotion & Facilitation Agency, India allocated an investment budget of US$ 1.4 trillion in infrastructure under the National Infrastructure Pipeline by 2025, of which 18% accounted for roads and highways, 17% accounted for urban infrastructure, and 12% for railways. Masterbatch is used in various applications in the construction of commercial buildings, warehouses, and power stations. Key market players offer UV additive, anti-static and flame-retardant masterbatches, offering durability and extension of structure life. The development of biodegradable and compostable masterbatch is expected to be a masterbatch market trend during the forecast period.

According to the National Bureau of Statistics of China, the country is the world’s largest producer of plastics; it produced ~8 million metric tons of plastic products between August 2020 and August 2021. China is the manufacturing hub for many sectors; therefore, the demand for masterbatches is expected to grow as the end-use industries expand. Masterbatches are widely used in the automotive and construction industries for various applications. The rising investments and production in the construction, plastic packaging, and automotive industries boost the masterbatch market growth.

Rising Demand for Black Masterbatches from End-Use Industries Drives Masterbatch Market Growth

The masterbatch market report emphasizes the key factors driving the market. Black masterbatch is a cost-effective and widely preferred option in the masterbatch market. It is mostly used in packaging applications for products such as films, bags, bottles, and containers. It provides opacity, UV protection, and aesthetic appeal. Black masterbatch is also suited for the production of hoses and geomembranes due to its properties such as UV and thermal protection. In the automotive industry, black masterbatch is used for interior and exterior components, including dashboards, door panels, trims, and bumpers. Automotive companies use black masterbatch in the production of external body panels, upholstery, and interior trims of luxury cars. According to L’Avere-France, 35,320 passenger plug-in electric cars were registered in the country in March 2023.

In the construction industry, masterbatch products are utilized for a variety of applications to enhance the performance, durability, and aesthetics of construction materials. Black masterbatch is used to add black color to plastic construction materials such as pipes, fittings, profiles, and roofing materials. Black masterbatch is widely used in the production of plastic pipes and fittings for plumbing and drainage systems. It provides UV resistance and color stability, ensuring durability of pipes. In February 2023, China launched an inbound investment program called the Qualified Foreign Limited Partnership (QFLP), which involved at least US$ 4.37 million of fundraising in its first round. The scheme is aimed at investing in residential and commercial housing projects. Thus, the rising demand for black masterbatches from end-use industries influences the masterbatch market growth.

Masterbatch Market: Segmental Overview

The masterbatch market analysis has been carried out by considering the following segments: type, polymer, and end-use industry. Based on type, the market is segmented into white, black, additives, color, filler, and others. In 2023, the white segment held the largest masterbatch market share. The color segment is expected to register the highest CAGR from 2023 to 2031. White masterbatch is a type of additive used as a colorant in polymer manufacturing. It provides white tones to the colorants. White masterbatch is added to a base resin to enhance its optical and physical properties, providing plastic products with their signature white color and propelling overall durability. Color masterbatch is a color concentrate granule used for coloring thermoplastics. It comprises one or more colorants and a polymer-specific carrier resin. Color masterbatch is mainly used as a colorant added in the plastic processing process to make plastic products form their intended colors.

Based on polymer, the market is segmented into polyethylene, polypropylene, polyethylene terephthalate, polystyrene, and others. The polyethylene segment held the largest masterbatch market share in 2023, and the polypropylene segment is expected to register a significant CAGR from 2023 to 2031. Polyethylene-based masterbatch is a concentrated blend of additives and a base polymer, polyethylene, which is designed to improve the properties of plastics and other materials. Polyethylene is widely used in thermoplastics due to its versatility, affordability, and compatibility. The masterbatch utilized in polypropylene resins is used to enhance the properties of polypropylene-based plastic products such as color, UV resistance, flame retardance, and antimicrobial properties. Polypropylene-based masterbatch is used in polypropylene products such as woven bags, weaving tapes, and bands to offer anti-splitting and anti-fibrillation effects. Masterbatches used for polyethylene terephthalate are concentrated mixtures of pigments, additives, and polymers added to polyethylene terephthalate to improve its properties such as color, strength, and processing capacity. Masterbatch is majorly utilized for bottles, film resin, and other products made of polyethylene terephthalate.

Masterbatch Market: Competitive Landscape and Key Developments

Avient Corp, Ampacet Corporation, Cabot Corp, LyondellBasell Industries NV, Plastika Kritis SA, Penn Color Inc, Americhem, FRILVAM SPA, Polyvel Inc, and Vanetti Spa are a few players profiled in the masterbatch market report. Players operating in the market focus on providing high-quality products to fulfill customer demand.

Key Developments (as per Company Press Releases):

- In 2023, Ampacet Corporation introduced ProVital + GermsClean, a medical-grade antimicrobial masterbatch developed to protect plastic components in healthcare facilities. It offers protection from a wide range of pathogens.

- In 2023, Ampacet Corporation introduced ColorMark, masterbatch additive technology. The developed product is compatible with polypropylene, polystyrene, polycarbonate and polyamide. The masterbatch produces permanent and weather-resistant color, available in six popular colors, namely, red, orange, yellow, green, blue and purple.

- In 2023, Penn Color Inc opens its first production plant in Thailand. The company aims to supply high-quality colorant and additive masterbatch to markets throughout the Asia Pacific.

- In 2023, Cabot Corporation launched REPLASBLAK, circular black masterbatch composed of sustainable material. The company launched three black masterbatch products, that includes REPLASBLAK rePE5475 100% circular black masterbatch, REPLASBLAK rePE5265 70% circular black masterbatch and REPLASBLAK rePE5250 60% circular black masterbatch.