Cling Films Market

The healthcare and pharmaceutical industries stand at the forefront of innovation and precision, demanding solutions for packaging that ensure the safety and integrity of products. With increasing advancements in medical technology and a surging aging population, there is a rising requirement for efficient and reliable packaging options to ensure the integrity and safety of medical devices, surgical instruments, and pharmaceutical products. Cling films play a crucial role in this context, providing a sterile barrier that helps prevent contamination and maintain product quality throughout the supply chain. In the healthcare sector, cling films are also extensively used for packaging sterile medical supplies such as bandages, gauze pads, and catheters. These films help maintain the sterility of these items, reducing the risk of infections and ensuring patient safety. Moreover, cling films are employed in packaging surgical instruments and medical equipment, providing a protective barrier against dust, moisture, and other contaminants.

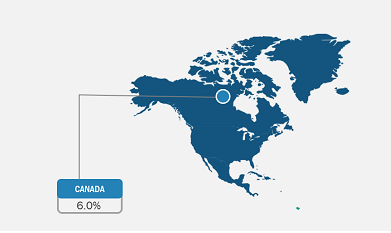

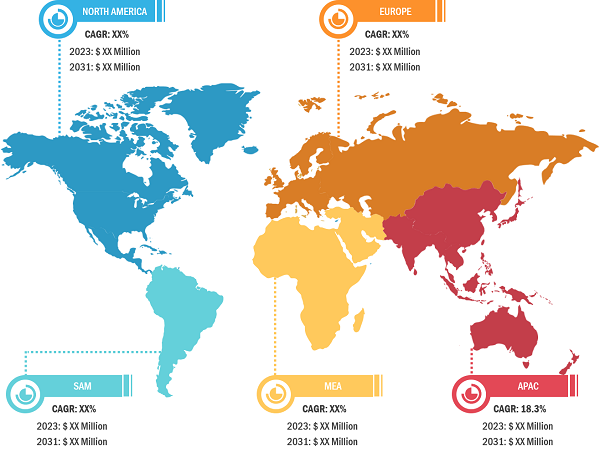

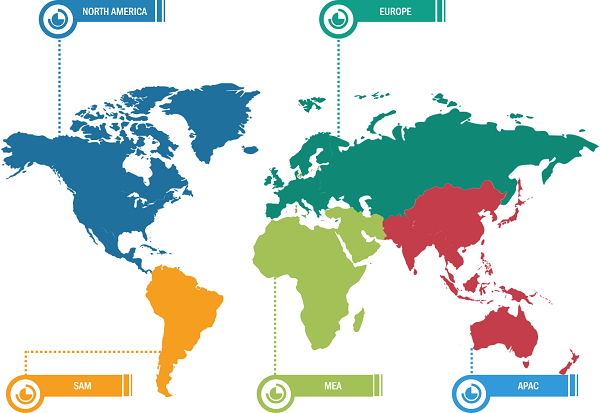

In the pharmaceutical industry, cling films are utilized for packaging tablets, capsules, and other dosage forms. These films help protect the medication from moisture, light, and air exposure, which can degrade the efficacy of the product. Additionally, cling films are used for blister packaging, where individual doses of medication are sealed in pockets, ensuring accurate dosing and tamper-evident packaging. According to the European Federation of Pharmaceutical Industries and Associations, in 2022, North America accounted for 52.3% of world pharmaceutical sales. Cling films have wide applications in the pharmaceutical industry in the packaging of healthcare and pharmaceutical products. Thus, the growing healthcare and pharmaceutical industries across the world, owing to factors such as increasing population, surging healthcare expenditure, and rising prevalence of chronic diseases, propel the demand for cling films.

The US and Germany are among the largest drug manufacturers in the world. According to the National Association of Manufacturers, the healthcare & pharmaceuticals industry recorded ~US$ 35.5 billion in value-added output in the US as of 2021. The industry fuels the other sectors of the economy such as the packaging industry. Cling films are widely used in the packaging of pharmaceutical drugs as they provide tamper resistance and protection from external conditions such as dust and moisture to avoid product contamination. Thus, the growing healthcare & pharmaceutical industry drives the demand for cling films.

Cling Films Market: Segmental Overview

Based on material type, the cling films market is segmented into low density polyethylene, biaxially oriented polypropylene, polyvinyl chloride, polyvinylidene chloride, and others. The low density polyethylene segment held the largest market share in 2023 and is expected to register the highest CAGR from 2023 to 2031. Low density polyethylene (LDPE) cling film is a versatile and widely used material in domestic and industrial applications. It is made from LDPE, a thermoplastic derived from the polymerization of ethylene, characterized by its low density and high ductility. The material exhibits excellent clarity, flexibility, and stretchability, which makes it ideal to wrap and preserve food items. The clinginess of LDPE cling film ensures a tight seal, which helps maintain the freshness and moisture content of food while preventing contamination and odor transfer. LDPE cling film is also used in packaging non-food items due to its resistance to tearing and punctures, providing a reliable protective barrier. Additionally, its relatively low melting point and ease of processing make it a cost-effective option for manufacturers.

Based on form, the cling films market is bifurcated into cast cling film and blow cling film. In 2023, the cast cling film segment held a larger market share. Cast cling films are made by horizontally extruding melted resin through a flat die to create a sheet of material. This material is pinned to a highly polished chiller roll with the help of an air curtain or a vacuum box. The film is cooled with additional chill rollers before trimming and rolling. Cast cling films are minimally pre-stretched, allowing improved depth of drawing for thermoforming operations. Besides, the polyolefins are evenly distributed in cast cling films due to the increased gauge consistency as a result of the manufacturing process involved. These films are clear with the linear alignment of resin molecules and excellent puncture resistance.

Based on end use, the cling films market is segmented into food, healthcare and pharmaceuticals, consumer goods, industrial, and others. In 2023, the industrial segment held the largest cling films market share. Cling films protect industrial products from external harm during logistics and storage. These films can handle different types of loads and safeguard the products from weather dynamics and moisture. Industries make use of cling films as a layer of primary covering to the material for merging two or more industrial products or binding them with cling films. The application of cling films in industrial uses saves freight costs, promotes safety in transit, decreases the pallets of goods, and increases the shelf life of industrial goods. PVC decorative cling film is an environmentally friendly material. It is applied to the surface finishing of flooring, furniture, speakers, and doors. PVC decorative films can also be used with glue for interior decoration. Some cling films are used for advertising as cold laminating films without liners for surface protection. LDPE cling films possess good electrical insulating properties; thus, they are used in the electronics industry in the form of screen guards in mobile phones and as coverings in speakers, cameras, televisions, and washing machines. Various cling films find their application in the manufacturing of plastic parts such as molded laboratory equipment and computer components. Plastic bags made of cling films protect industrial products from dust, rain, and transit damage. The cling films used for industrial purposes mainly possess high resilience, transparency, and good gloss with high tensile strength.

Cling Films Market: Competitive Landscape

Berry Global Group Inc, Adex S.r.l., Anchor Packaging LLC, Cedo Ltd, The Interpublic Group of Companies Inc, MOLCO GmbH, Multiwrap, Dow Inc, POLIFILM, and Mitsubishi Chemical Group Corp are among the key players operating in the global cling films market. Market players focus on providing high-quality products to fulfill customer demand.