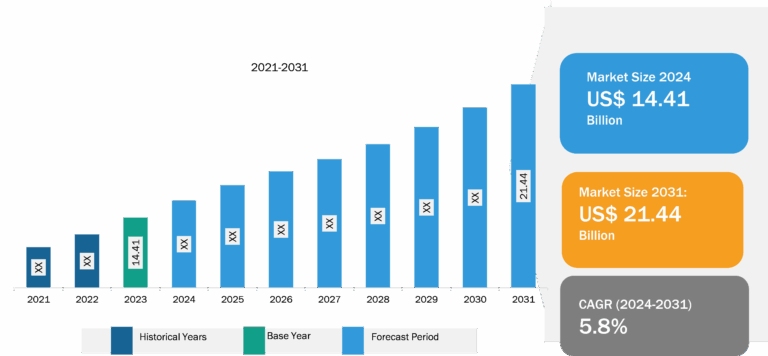

Anticorrosion Coatings Market

In 2022, the Middle East & Africa held a significant anticorrosion coatings market share. The demand for high-performance coatings has escalated significantly in the Middle East as it is a global hub for oil & gas production. According to the National Iranian Oil Company, Iran has ~158 billion barrels of crude oil reserves. As per the data from Gachsaran Oil & Gas Production Company, the oil field, which has been in operation since 1930, currently produces 650,000 bpd (Barrel Per Day) of oil. The market in the Middle East has undergone substantial expansion in recent years owing to the region’s dynamic industrial landscape and burgeoning infrastructure projects. The continuous development of oil & gas facilities, pipelines, and marine structures has upsurged the need for advanced anticorrosion coating solutions. The global anticorrosion coatings market size is likely to increase by 2030 owing to the strong growth of the building & construction industry.

Strong Presence of Oil & Gas Industry Drives Anticorrosion Coatings Market Growth

Various countries in the Middle East play a vital role in global oil production. Saudi Arabia, Iran, the UAE, and other oil-producing countries in the region comprise many of the largest oil producers. Presence of oil reserves plays a crucial role in the economic growth of different countries in the region, as most of their income depends on the oil industry. According to the Organization of the Petroleum Exporting Countries, Saudi Arabia possesses around 17% of the world’s proven petroleum reserves. The country also ranks as one of the largest net exporters of petroleum. The oil & gas industry of the country accounts for ~40% of the gross domestic product (GDP). According to the US Energy Information Administration, Saudi Arabia exported an estimated 7.3 million barrels per day of crude oil in 2022, an increase of 13% from 6.5 million barrels per day in 2021, as a result of increased annual crude oil production. In 2022, the energy minister of Saudi Arabia said that oil production capacity in the country would reach more than 1 million barrels per day to over 13 million barrels per day by the end of 2026 or the start of 2027. According to the International Trade Administration, the UAE is one of the world’s ten largest oil producers. In the UAE, Abu Dhabi has about 96% of the roughly 100 billion barrels of proven oil reserves; the country ranks number six worldwide. Thus, the rising offshore oil exploration and transportation activities contribute to the growing anticorrosion coatings market size. Additionally, the anticorrosion coatings market trends include rising preferences for environment-friendly and bio-based anticorrosion coatings.

Anticorrosion Coatings Market: Segmental Overview

The global anticorrosion coatings market scope is segmented into resin type, technology, and end-use. Based on resin type, the market is segmented into epoxy, polyurethane, acrylic, alkyd, vinyl ester, and others. The epoxy segment accounts for the largest anticorrosion coatings market share. Epoxy anticorrosion coatings, formulated with epoxy resins as their primary constituents, belong to the class of thermosetting polymers, imparting robustness and durability to the protective layer they create. Deployed across diverse industries such as oil & gas, maritime, automotive, and infrastructure, epoxy anticorrosion coatings serve as a frontline defense mechanism for metal surfaces. The application process involves the precise amalgamation of epoxy resins with curing agents, resulting in a chemically resistant and adhesive compound. Upon application, these coatings solidify into a tough, impermeable barrier that shields metal surfaces from corrosive agents, preventing oxidation and deterioration over extended periods. Based on technology, the market is segmented into solvent-borne, water-borne, and others. The water-borne segment accounts for the largest market share. Solvent-borne anticorrosion coatings are sophisticated formulations engineered to provide robust protection against the detrimental effects of corrosion, particularly on metallic surfaces. These coatings employ organic solvents as carriers for a meticulously crafted blend of components, each contributing to the coating’s effectiveness. The primary constituents include resins, which form the structural backbone of the coating; pigments that impart color and additional barrier properties; and corrosion inhibitors strategically integrated to thwart the corrosive process. The solvent component plays a pivotal role in the application process, allowing for ease of spreading and ensuring uniform coverage on the substrate. Upon application, the solvents facilitate the even distribution of the coating, penetrating surface irregularities and creating a seamless, protective film. Based on end-use, the market is segmented into marine, oil and gas, power, automotive, building and construction, aerospace and defense, and others. The utilization of anticorrosion coatings in the marine industry is imperative for preserving the structural integrity and longevity of vessels and marine structures subjected to harsh and corrosive marine environments. Seawater, with its high salt content, poses a significant threat to metal components, making corrosion a pervasive challenge. To overcome this, anticorrosion coatings are applied to these components. These coatings are precisely formulated to withstand the corrosive effects of saltwater, moisture, and atmospheric conditions. In marine applications, anticorrosion coatings find extensive use on ship hulls, offshore platforms, pipelines, and other submerged or exposed metallic structures. The coatings act as protective barriers, preventing direct contact between corrosive elements and the metal surface. The implementation of anticorrosion coatings in the oil & gas industry is critical for safeguarding infrastructure and equipment from the corrosive challenges posed by harsh operating environments. Pipelines, storage tanks, drilling equipment, and various components in the oil & gas sector are constantly exposed to corrosive elements such as moisture, corrosive gases, and chemicals.

Anticorrosion Coatings Market: Competitive Landscape

RPM International Inc, The Sherwin-Williams Co, Akzo Nobel NV, Jotun AS, PPG Industries Inc, 3M Co, The Progressive Center Co for Construction Chemicals Ltd, Nippon Paint Holdings Co Ltd, BASF SE, and HB Fuller Co are among the prominent players profiled in the anticorrosion coatings market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The anticorrosion coatings market report also includes company positioning and concentration to evaluate the performance of competitors/players in the market.